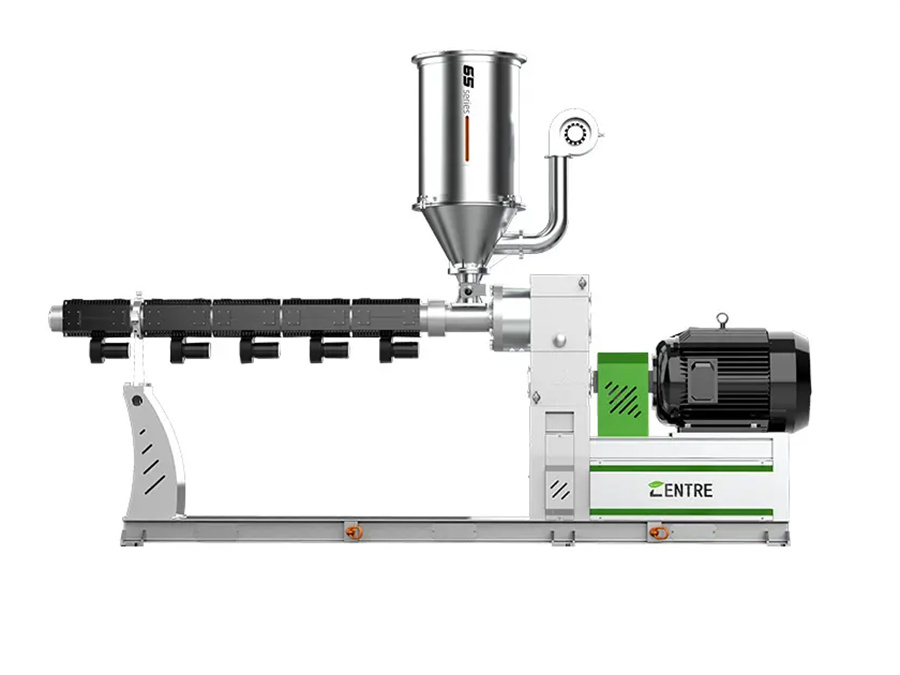

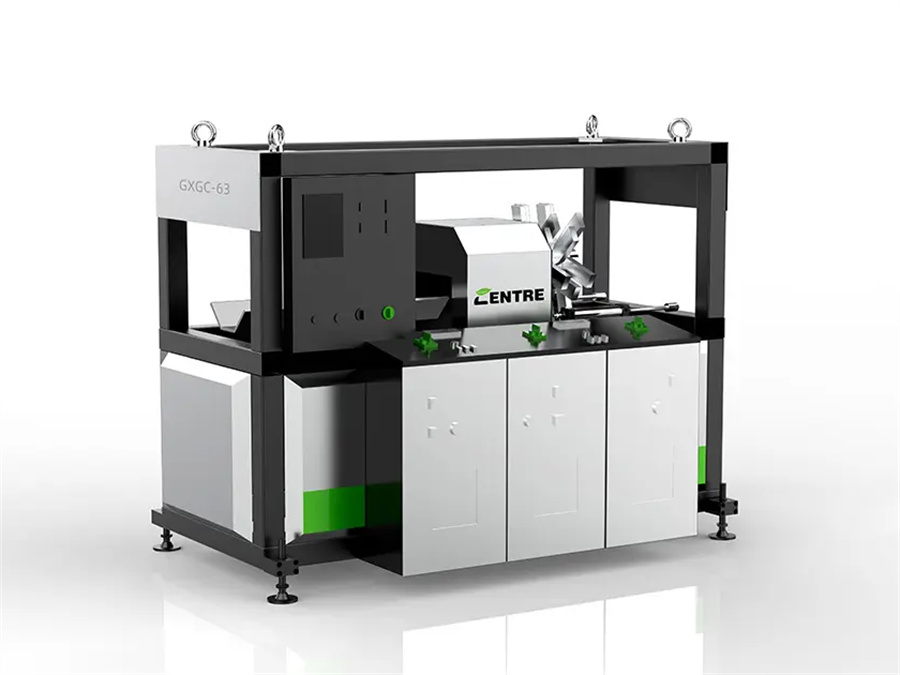

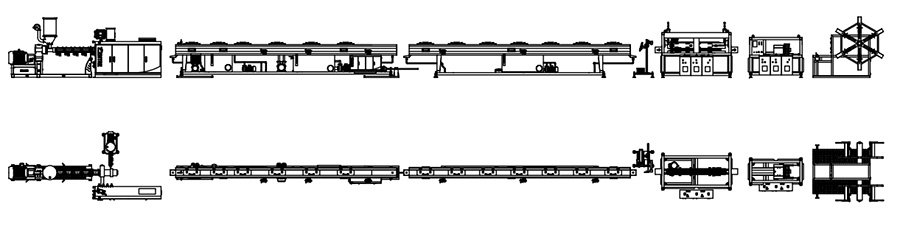

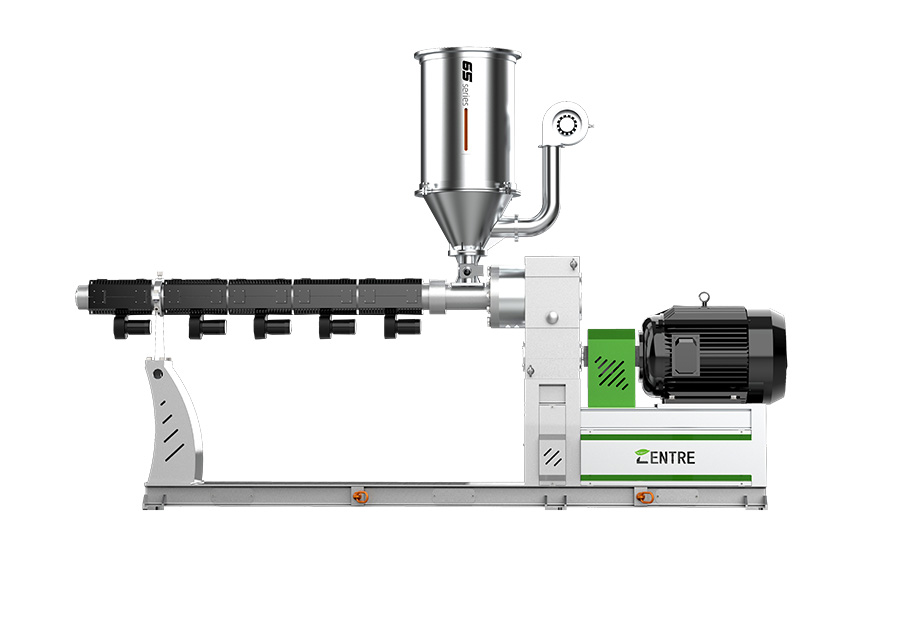

Energy-saving high speed polyolefin pipe

Main Technical Parameter

Model |

Diameter(mm) |

Extruder |

Capacity(kg/h) |

Power |

CTPE-110 |

20-110 |

CTSJ-60/38 |

120-250 |

130 |

CTPE-450 |

110-450 |

CTSJ-75*38 |

500-650 |

400 |

CTPE-800 |

315-800 |

CTSJ-90/38 |

700-940 |

600 |

CTPE-1600 |

710-1600 |

CTSJ-120/38&CTSJ-60/38 |

1600-1700 |

750 |

Color Line |

CTSJ-30/25 |

10-12 |

5 |

|

CTSJ-30/25 |

5-10 |

4 |

||

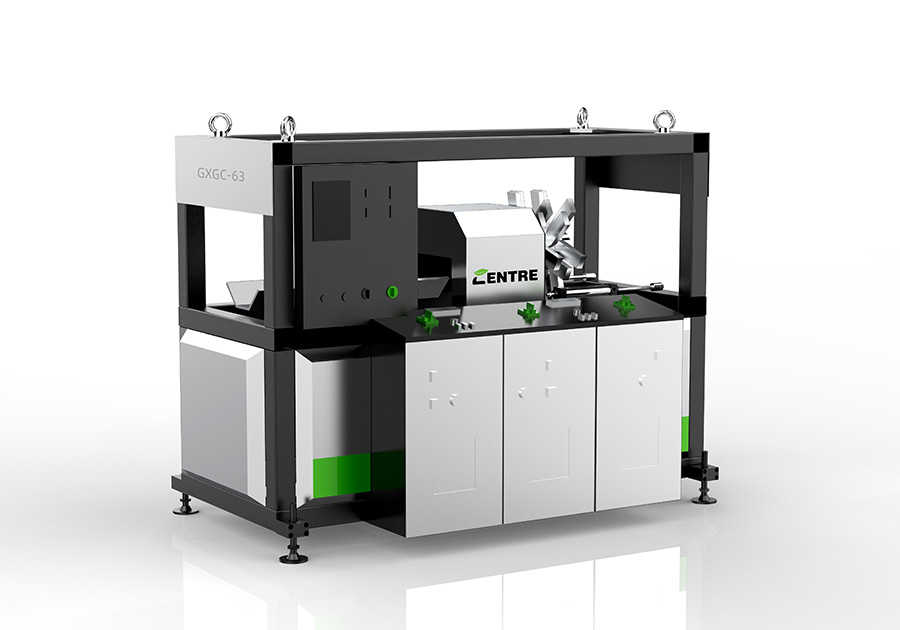

Features

1. New type screw with L/D 38:1. Capacity has been increased largely

2. The complete line adopts advanced PLC control system, realizing synchronization and full-automation

3. New type high torque gearbox realizes much more stable production

4. Vacuum calibration tank and cooling tank adopt automatic water temperature and water level control as well as special independent filters.

Electrical spare parts

All the machine inverters adopt to ABB brand ,Siemens or Schneider

This pipe extrusion line research&developed by CENTRE company, features of unique structure, easy controlling, highly automation and stable performance.pipes produced by this machine has the moderate rigidity, strength,as well as good flexibility, anti-rot,anti-stress split,and favorable hot melting, make this pipe considered as the prefer product for water and gas system in cities.