HDPE Pipe Extrusion Line(ABC)

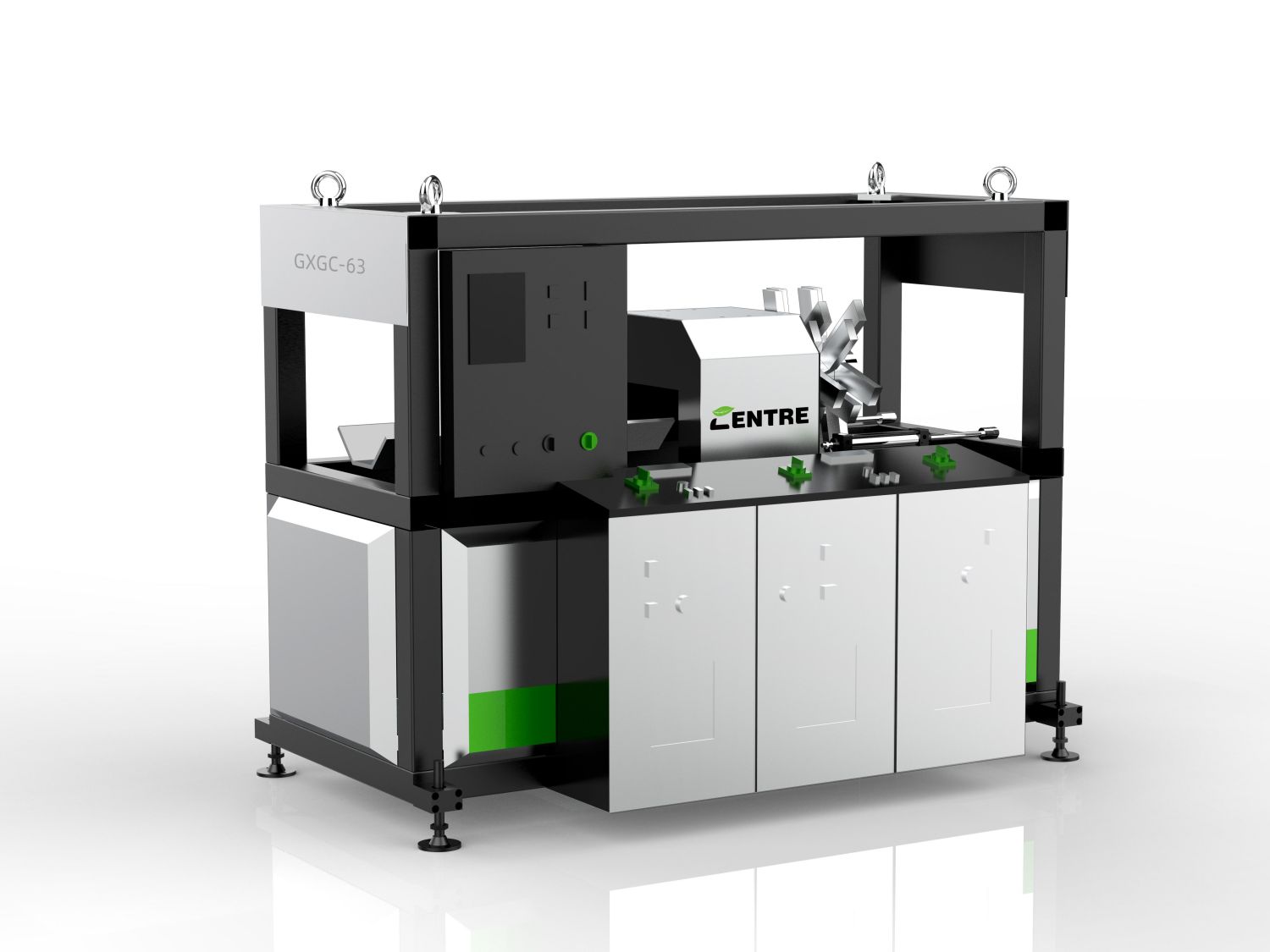

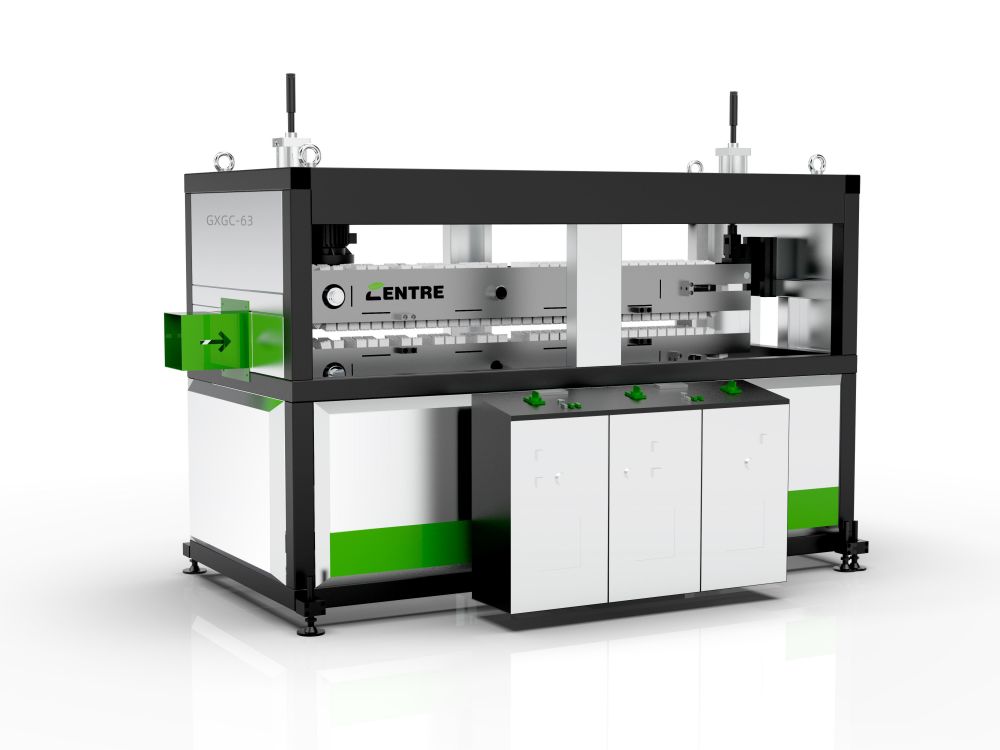

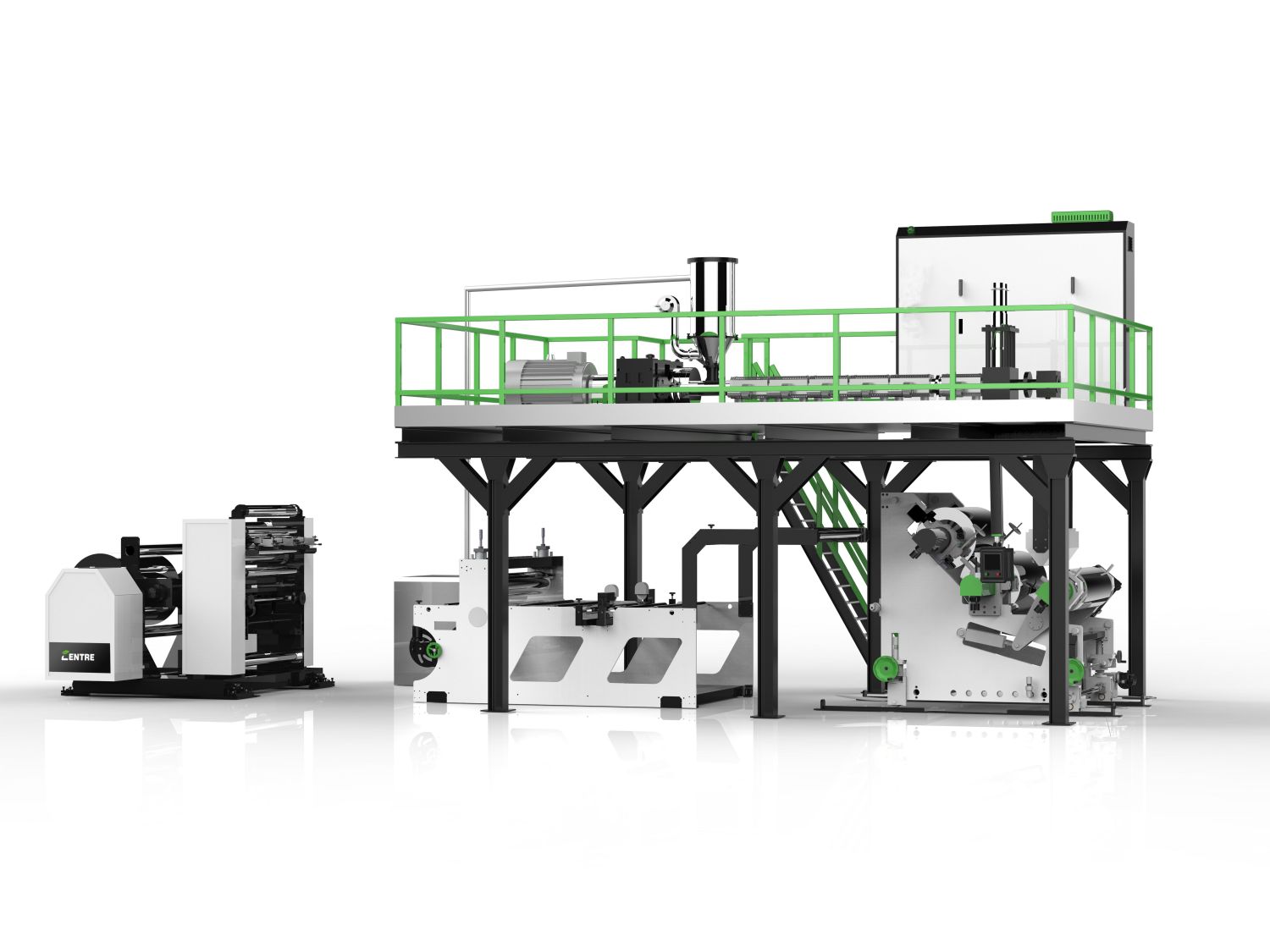

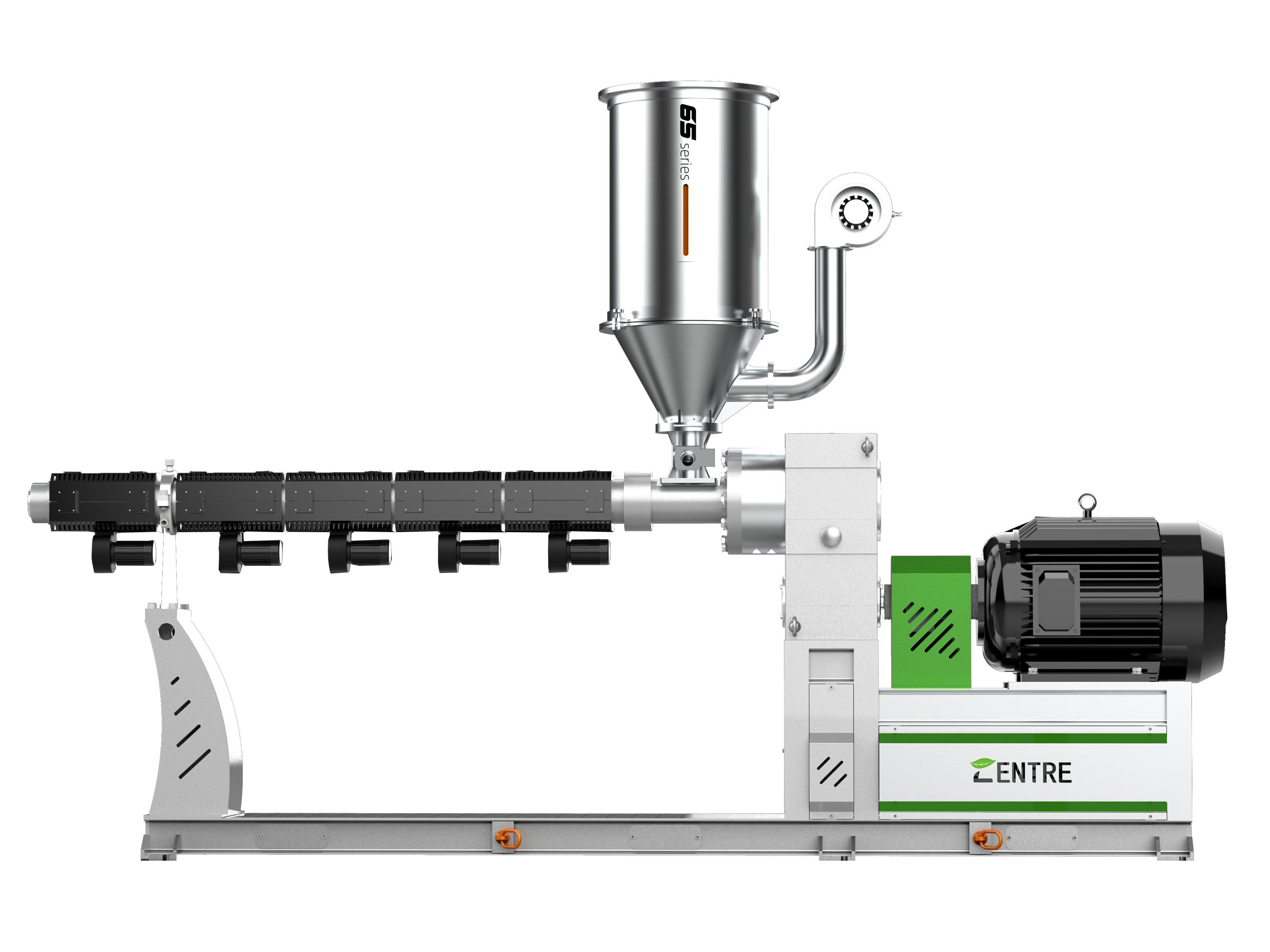

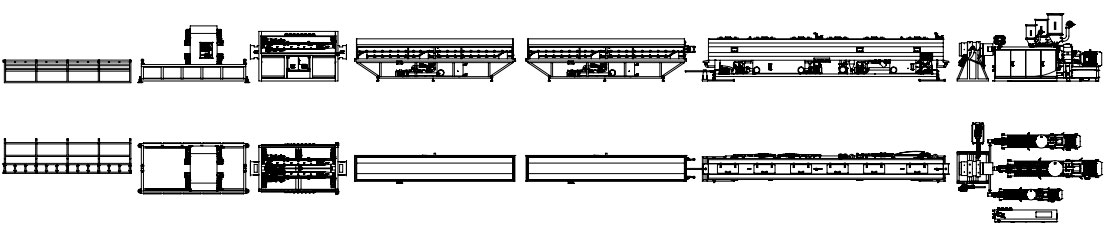

Based on 20 years of plastic extrusion machinery development and design experience,CENTRE combined the advance technology to prompt this HDPE water and gas pipe production line.It’s unique structure design and high efficiency performance makes it fast accepted by the pipe factories.The extrusion line consists of high efficiency single screw extruder, vacuum calibration, spraying water cooling tank, multi-claw haul-off machine,planetary cutting machine, pipe stacker and trolley.

HDPE pipe widely applied on gas and water transportation. The extrusion line can be used to produce two layer or three layer HDPE pipes also, which takes the recycled material on the outer layer or middle layer to decrease the cost.

Our advantage

The extruder uses a large aspect ratio screw and an AC motor to achieve high output and energy saving.

The mold body adopts independent spiral mechanisms in each layer to ensure uniformity, ensure stable melt temperature under high output, and reduce cooling length.

The vacuum pump adopts a special structure to drain water to reduce workshop noise.

The traction adopts servo control, and the speed adjustment range is large, ensuring stable production with high torque at low speed.

Using a chipless cutting machine, the cut length is clear and accurate, and the cut is beautiful.

Production data collection and analysis system can be selected to achieve transparent production management.