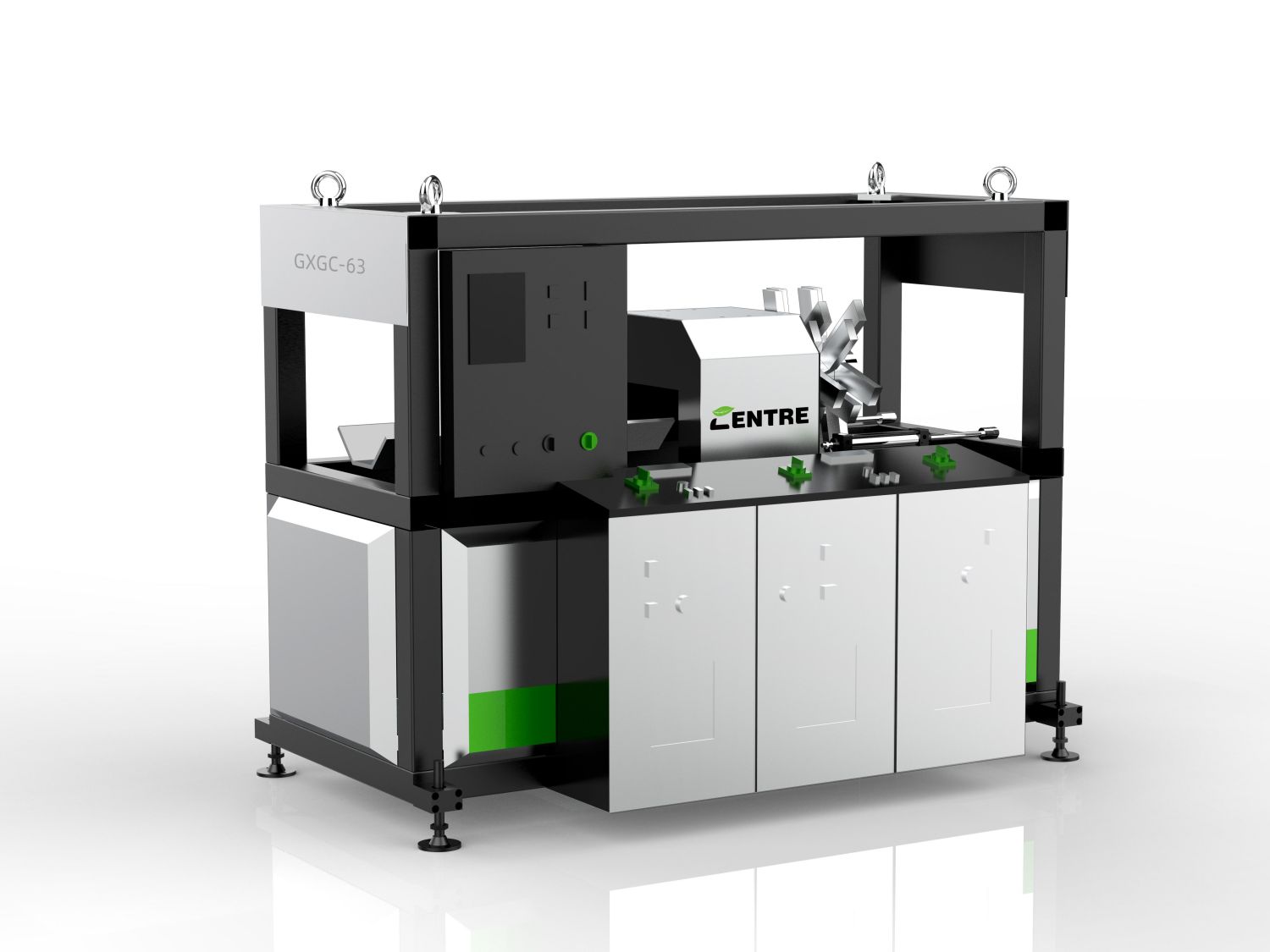

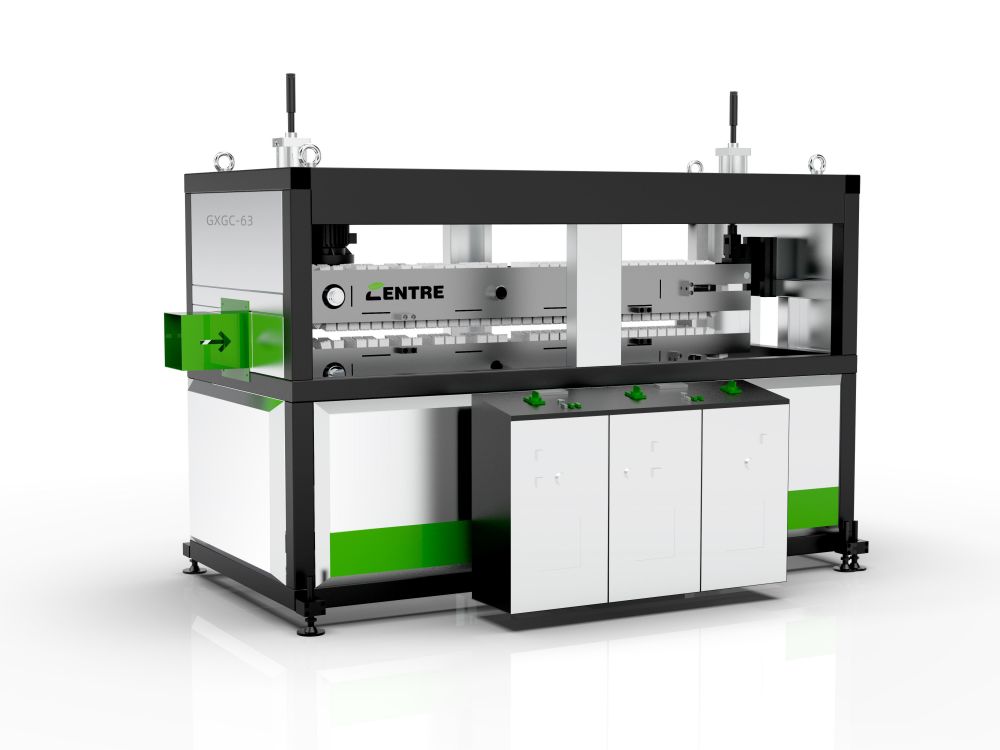

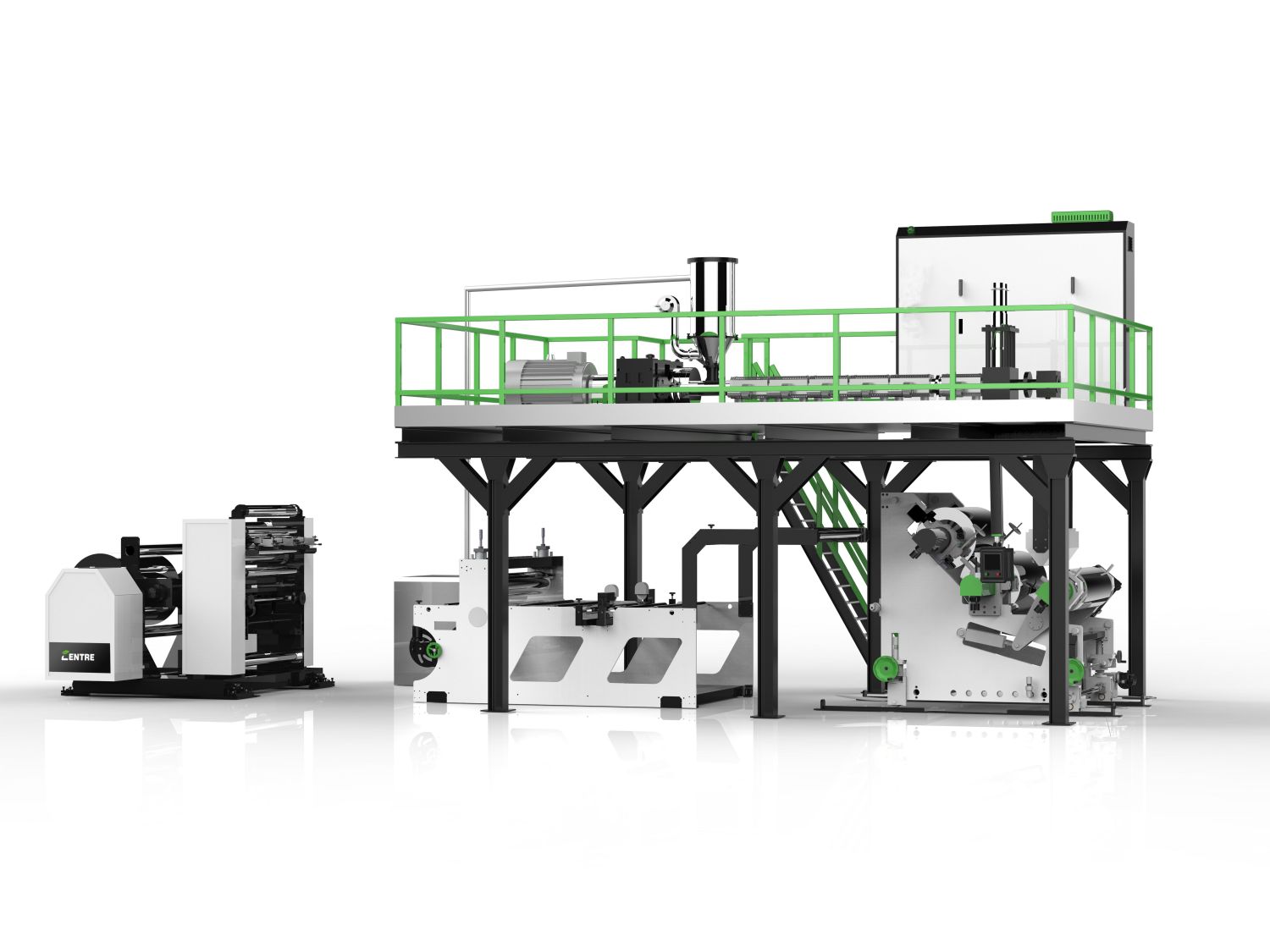

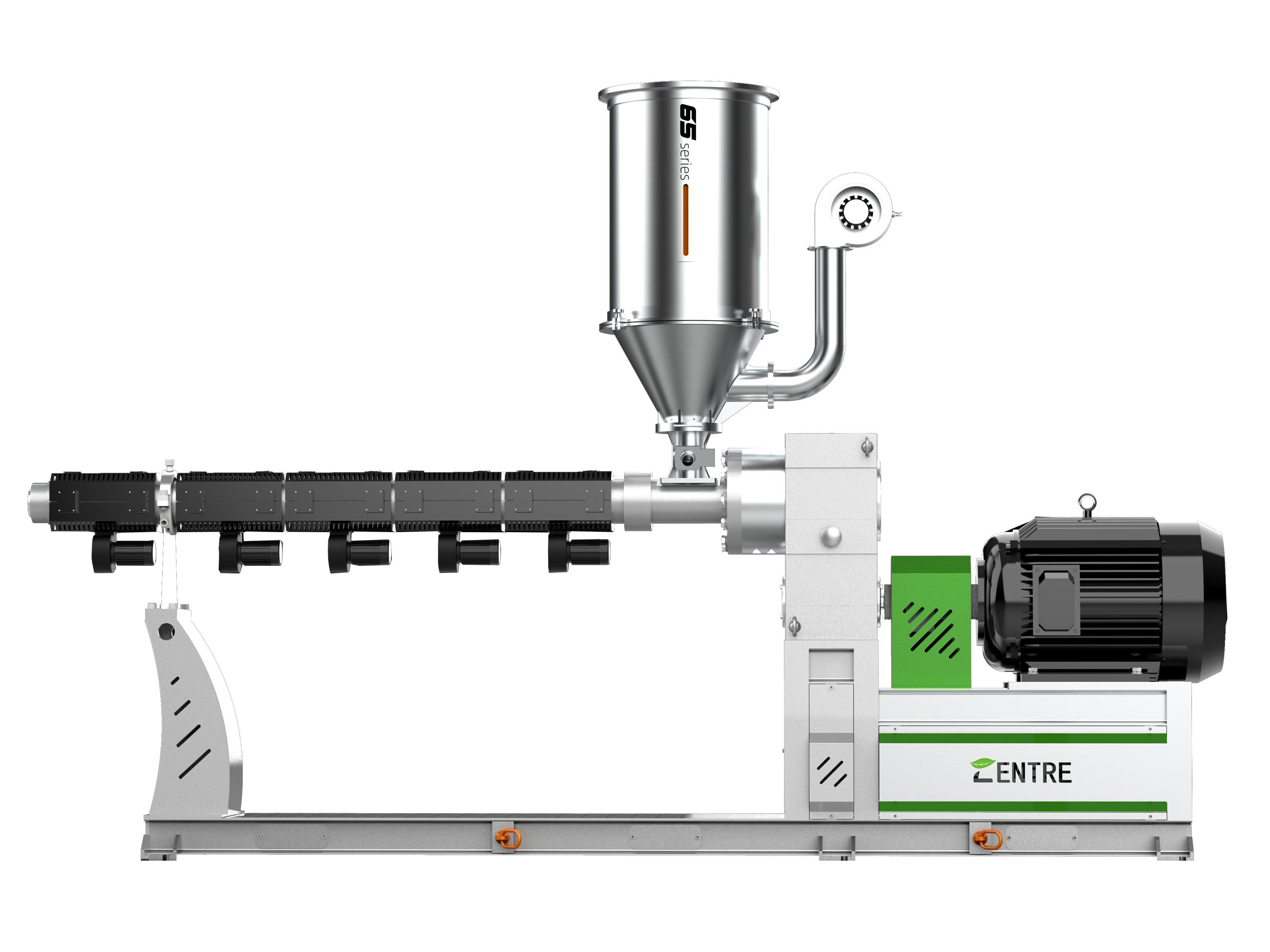

Single Screw Extruder for PE and PP Pipe Extrusion

The equipment is mainly used to extrude a series of thermoplastics such as PP/PE/PA. When paired with corresponding downstream equipment, it can produce different plastic products, such as pipes, sheets, plates, ribbons, etc. It has a wide range of uses and a large market space.

Our Advantages

- Top performance in the extrusion of smooth, corrugated and co-extruded pipes

- Excellent melt homogeneity and low melt temperatures

- Screw geometries for HDPE and PP processing

- AC motors for low energy consumption

- Extremely space-saving through high performance with small screw diameters

We Offers

- Screw diameter;CTSJ 30、45、50、55、60、65、90、100、120、150...........

- 25:1、30:1、33:1 、L/D ratio

- High installed screw torques for optimal specific throughput

- Outputs from 100 kg/h to 2,750 kg/h (6,000 lbs/hr)