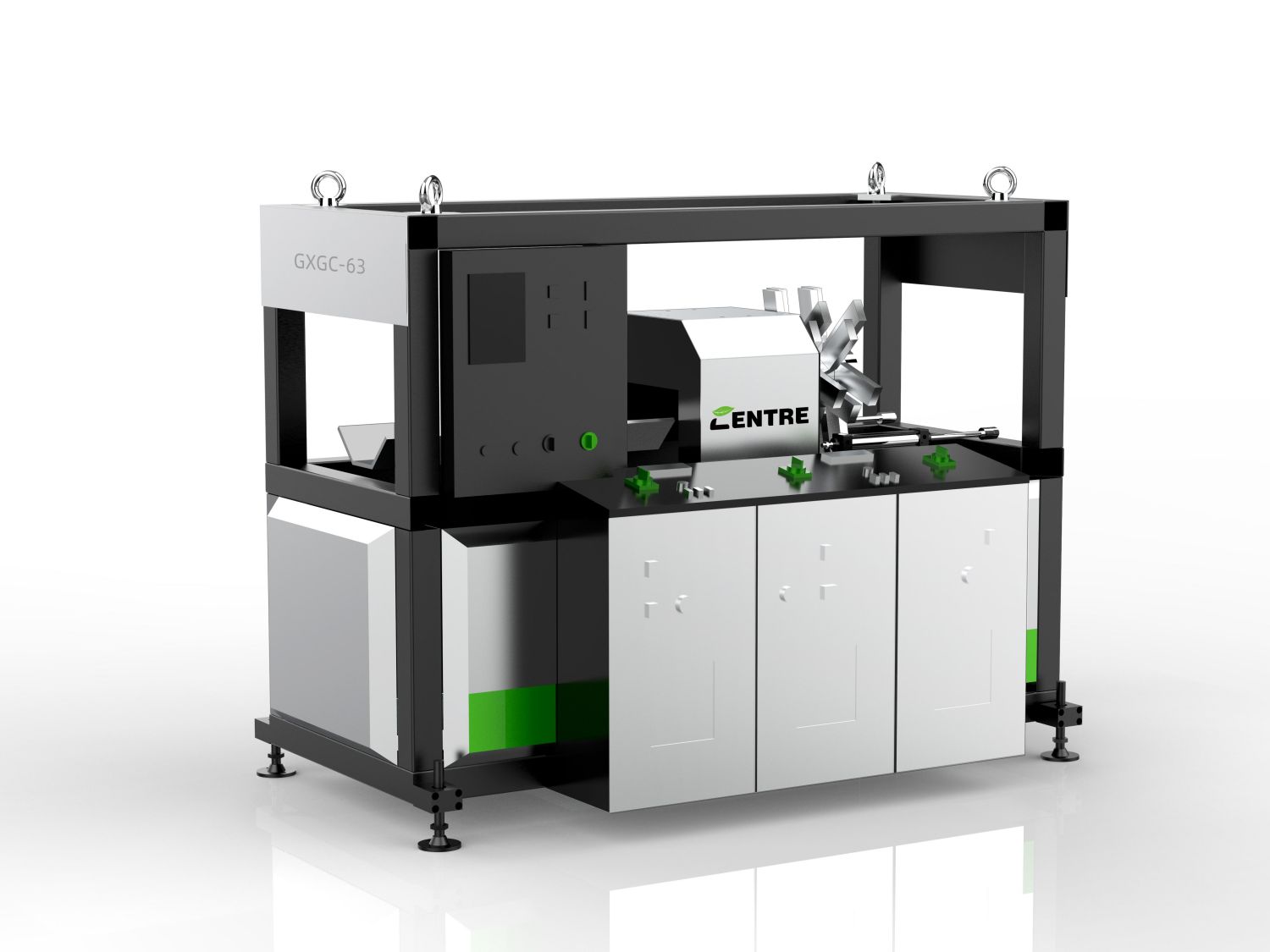

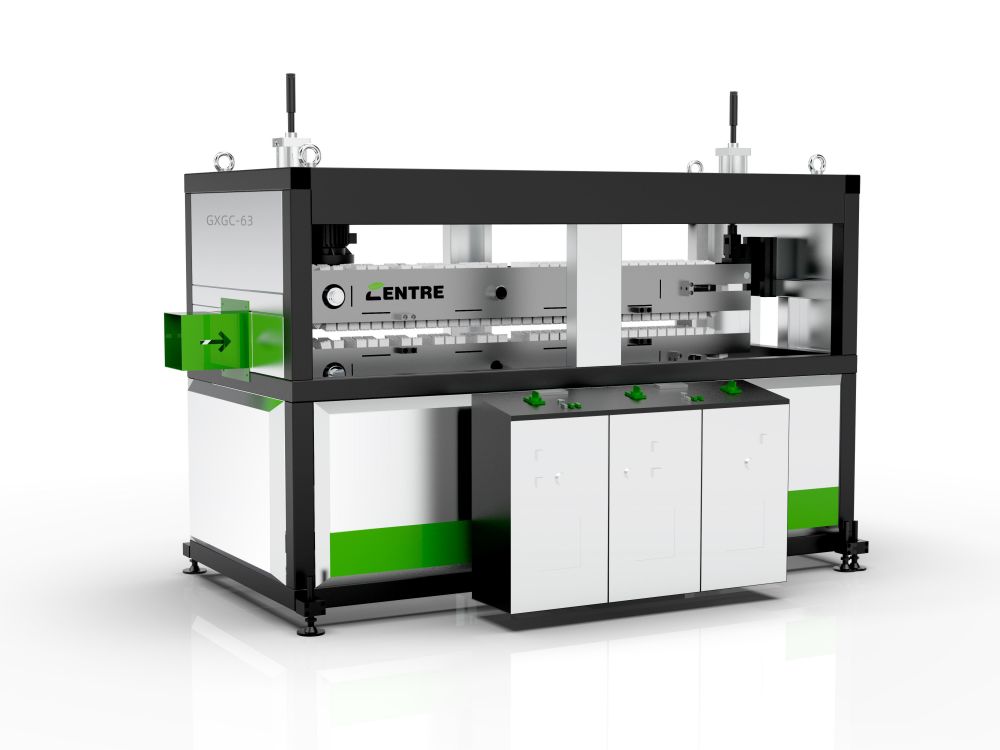

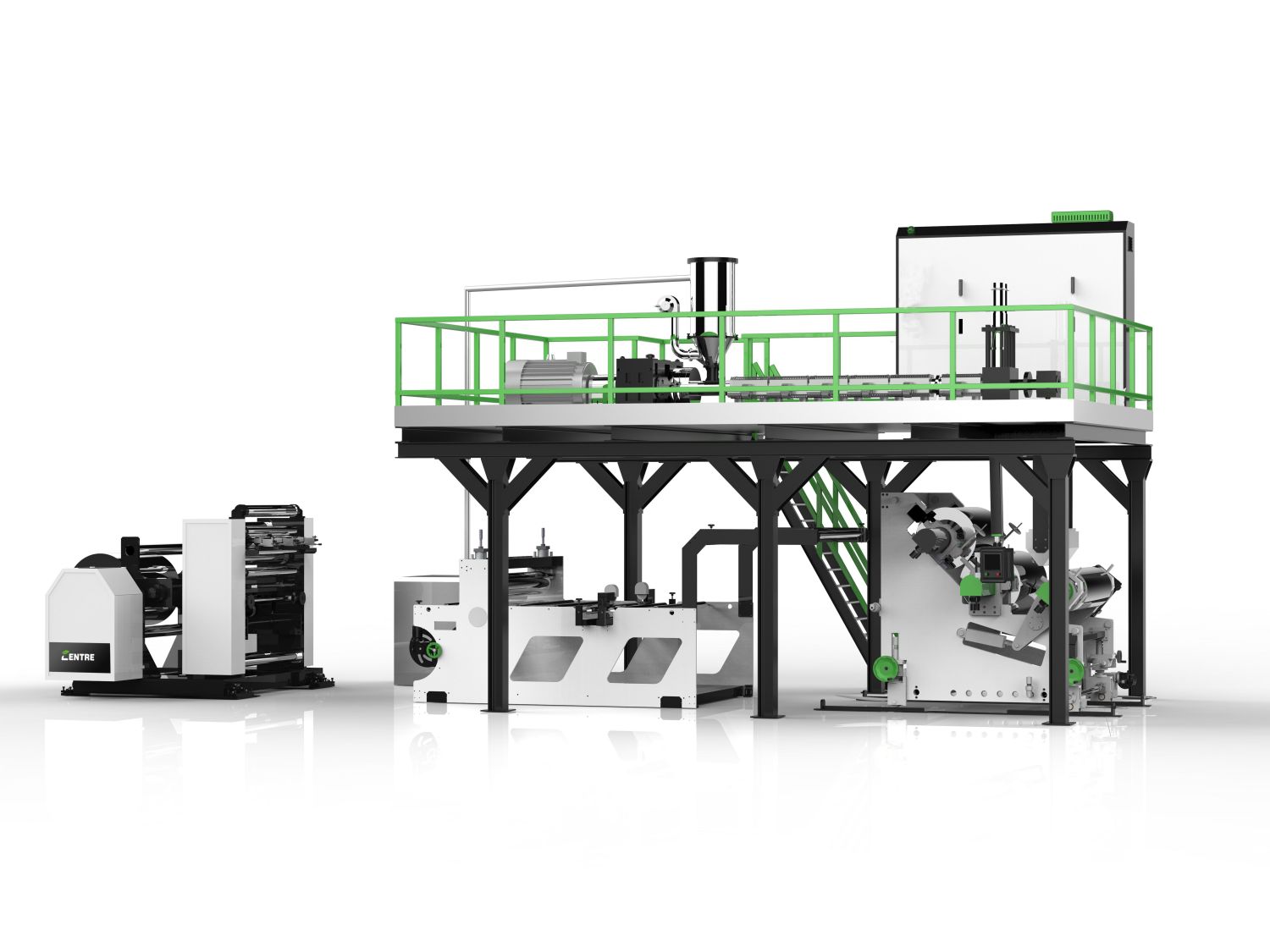

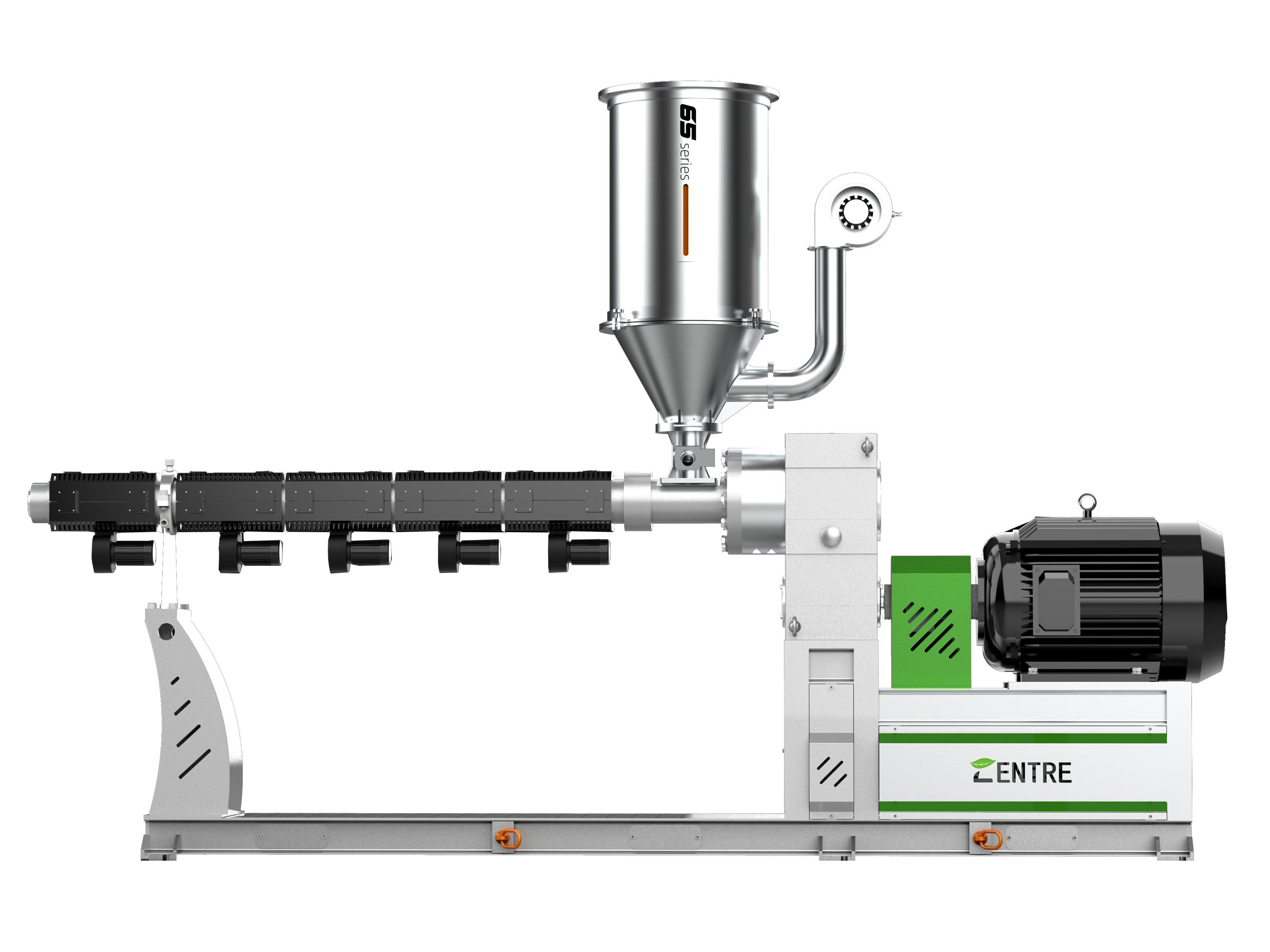

Centre Twin-screw extruder for PVC product production

Center's self-developed twin-screw basic equipment is also very convenient for subsequent maintenance. Internal problems can be discovered at any time for effective repair and replacement. Assembling the screw also greatly reduces the maintenance cost and time of replacing parts and avoids unnecessary waste.

Advantage

- Suitable for processing and manufacturing products of various materials such as PVC, wood-plastic profiles, various pipes, thermosetting plastics, heat-sensitive materials, etc.

- Excellent melt uniformity and low melt temperature.

- Low energy consumption AC motor.

- Screw diameter, high performance, extremely space-saving.

Classification

Twin screw specifications: SJ51/105, SJ65/132, SJ80/156, SJ90/188

Co-directional meshing, counter-meshing and non-meshing types in twin-screw extruders.

Nissan maintenance

1. After 500 hours of use, there will be iron filings or other impurities in the reduction gearbox. Therefore, the gears should be cleaned and the reduction gearbox lubricating oil should be replaced.

2. After using it for a period of time, conduct a comprehensive inspection of the extruder to check the tightness of all screws.

3. If there is a sudden power outage during production and the main drive and heating stop, when the power is restored, each section of the barrel must be reheated to the specified temperature and kept warm for a period of time before the extruder can be started.