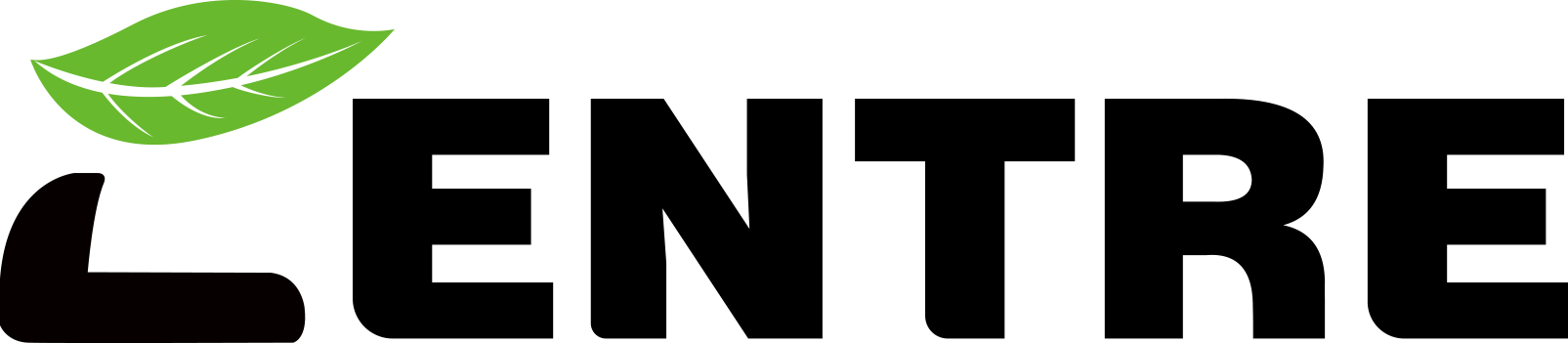

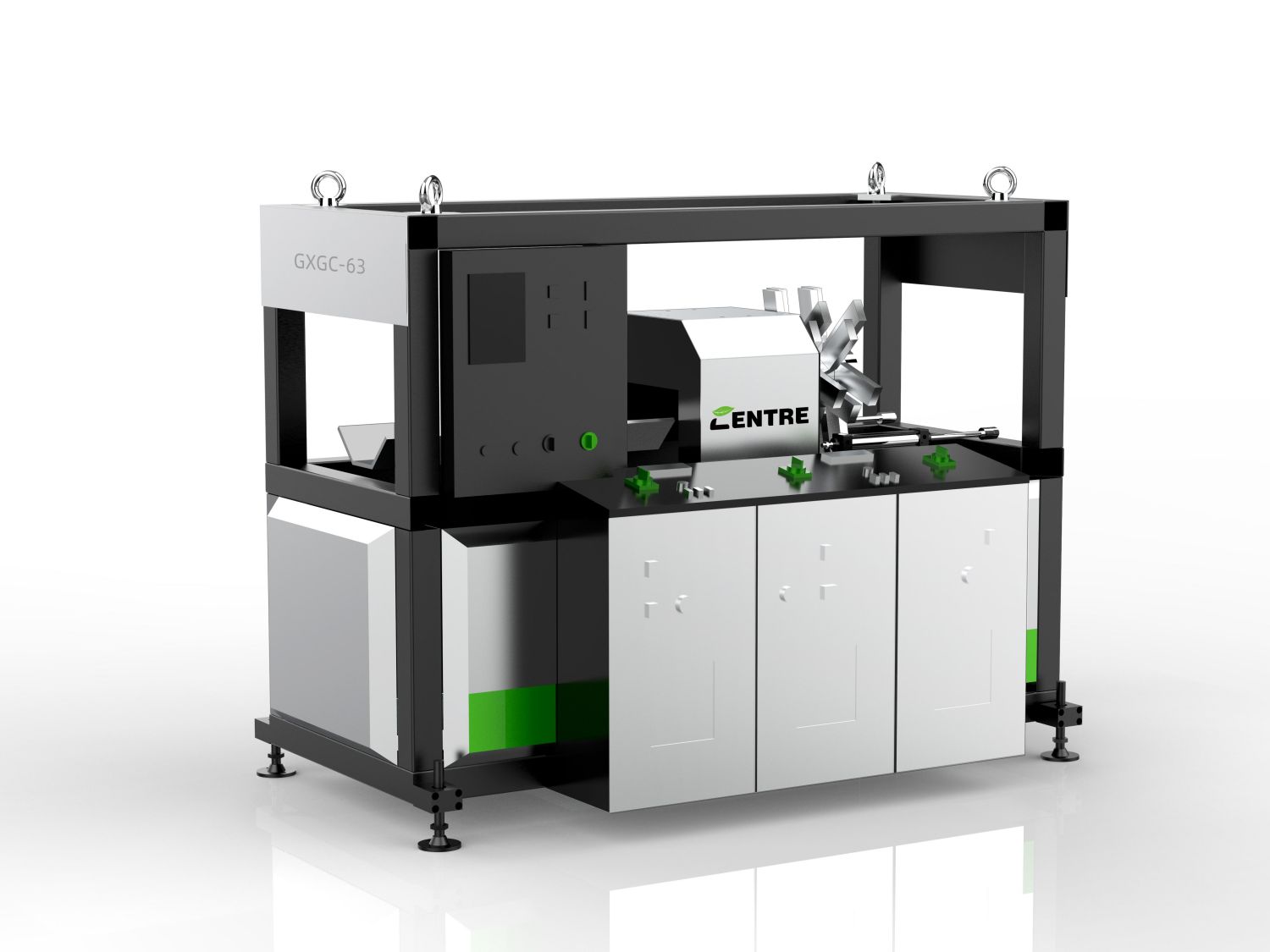

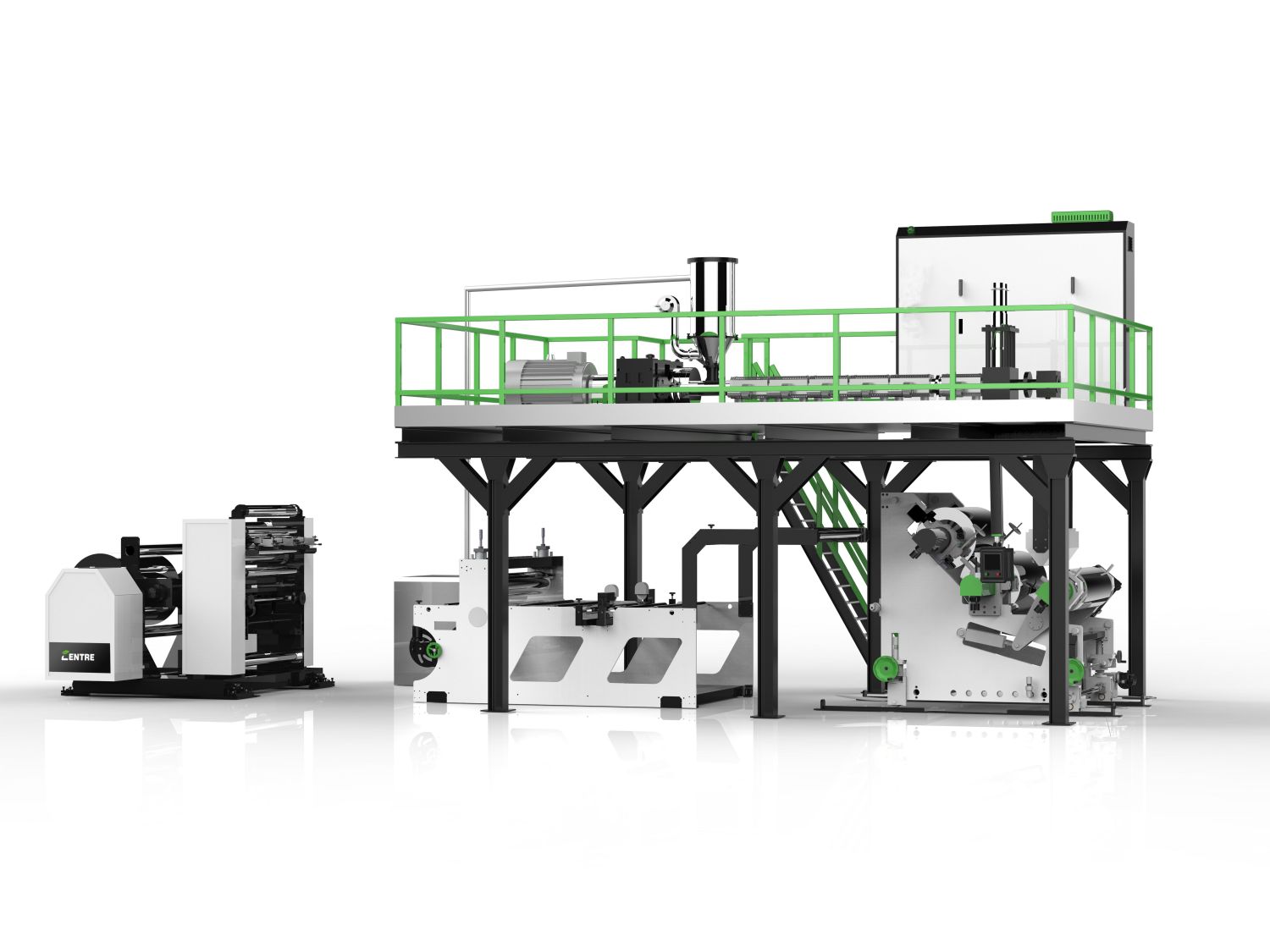

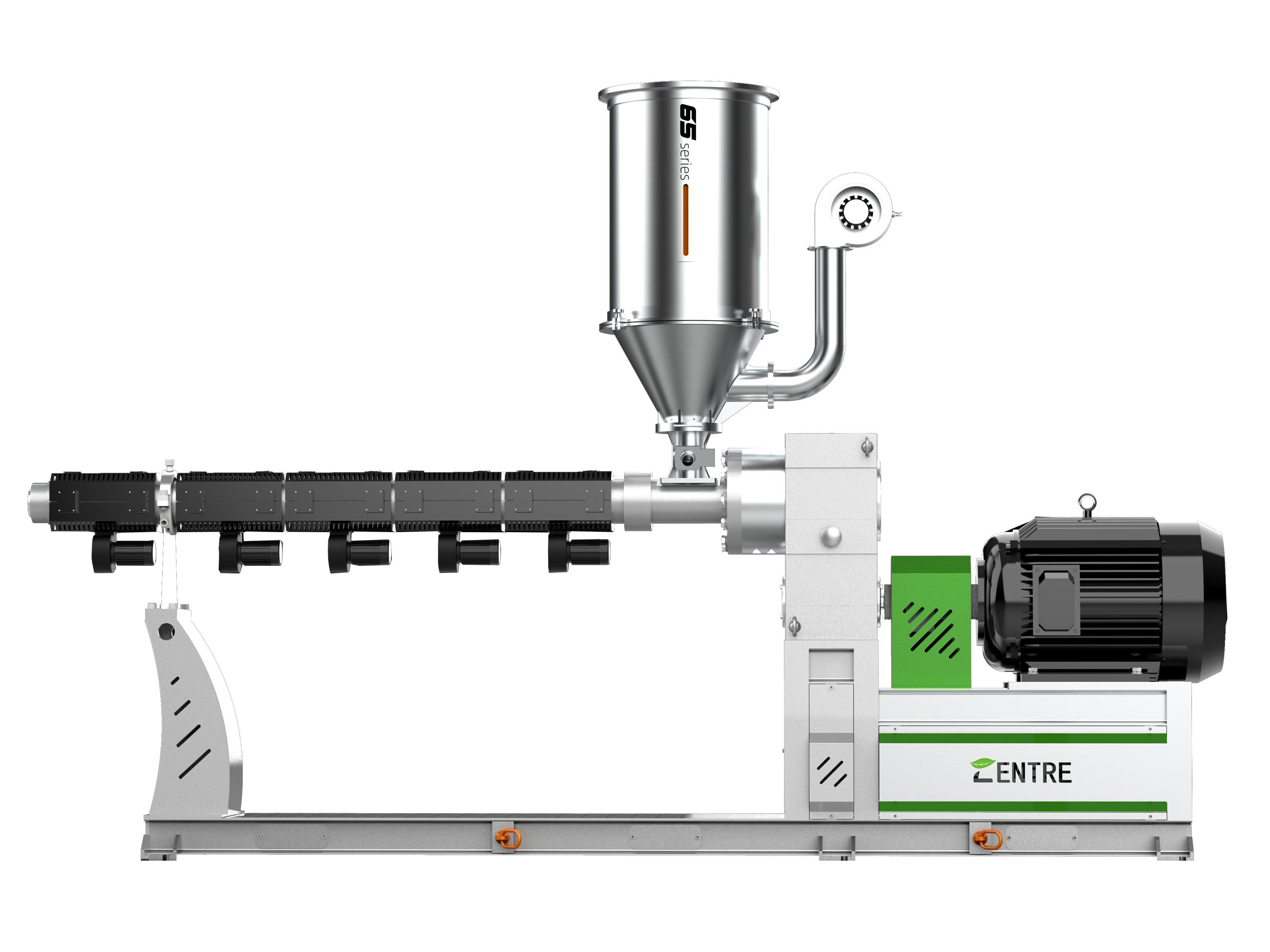

Cutting Machine For Pipe Extrusion Line

After the pipe is formed, it is fed into the machine at a set speed. When the feeding length reaches the specified value, the fixed-length travel switch sends a signal. After the machine receives the signal, the automatic cutting cycle starts.

First, the advancing pipe is clamped. At this time, the main body of the saw frame advances synchronously with the pipe. At the same time, the cutting motor starts and the feed motor starts to feed. When the feed reaches the specified value, the feed motor stops working and the main motor starts to revolve. , cutting starts at this time. After the main motor is placed for a week, the pipe is cut at this time. The feed motor begins to retract the knife. After the knife retraction is completed, the clamp begins to loosen and the return cylinder opens.

Our Advantages

- Best possible cut quality and cut surface with very different pipe materials

- Swarfless cutting across a very wide range of different pipe materials

- Perfectly synchronized with extrusion line and haul-off speed of the entire extrusion line

- Wide range of different pipe wall thicknesses can be separated in the best possible way using the central clamping system

- Machine cutting and chamfering of PVC pipes and other special applications possible