Vacuum Tanks For Pipe Extrusion Line

Our Advantages

- Complete solutions made from stainless steel

- Flow-optimized piping made of corrosion-resistant materials

- Easy height, horizontal and longitudinal adjustment

- Cold water temperature control

- Energy savings with the help of optimally designed pumps

- Tanks customized to the application requirements

- Patented pipe support system for the FDC version

- Vacuum pumps can be frequency controlled optional

Our Offer

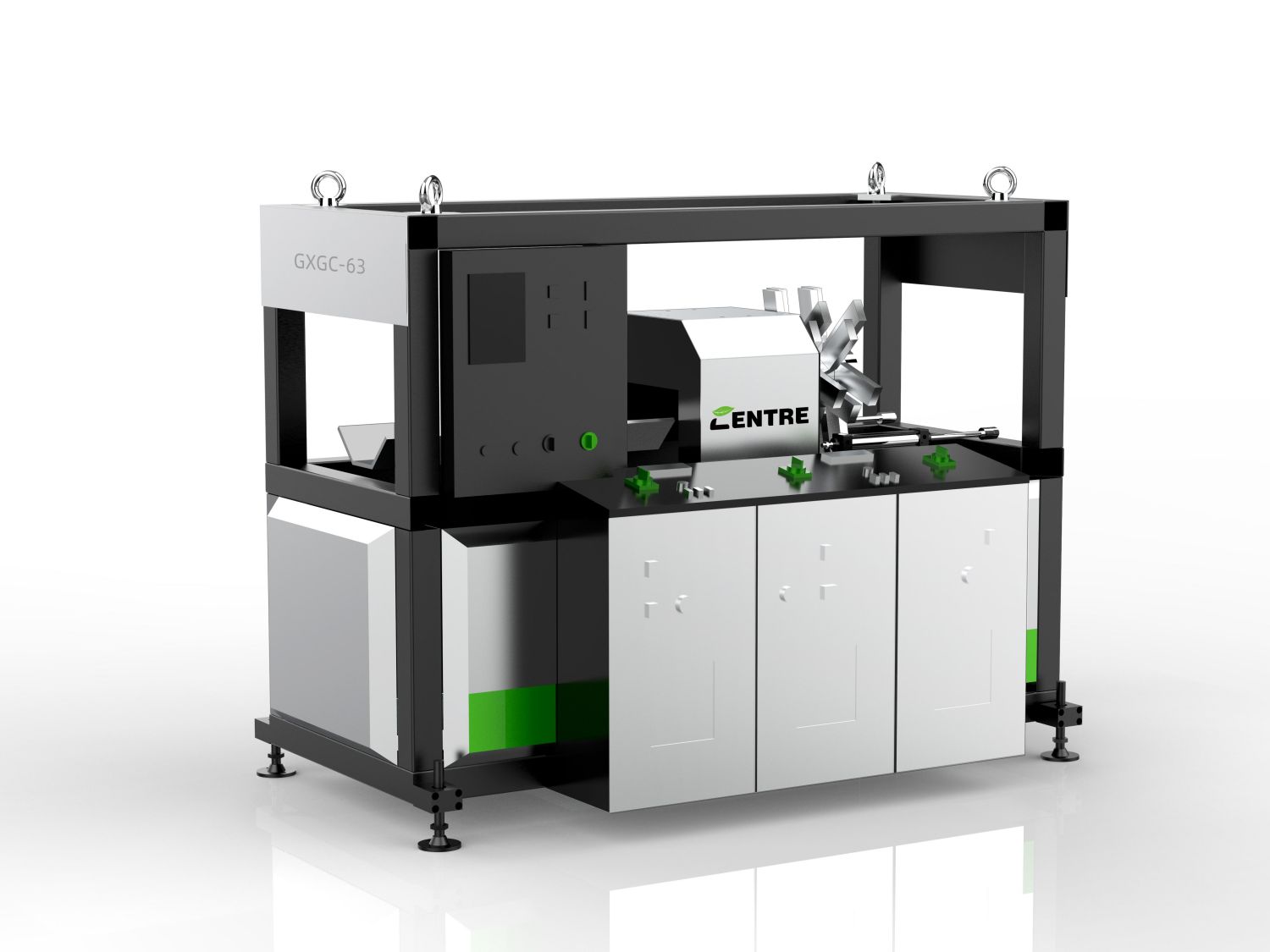

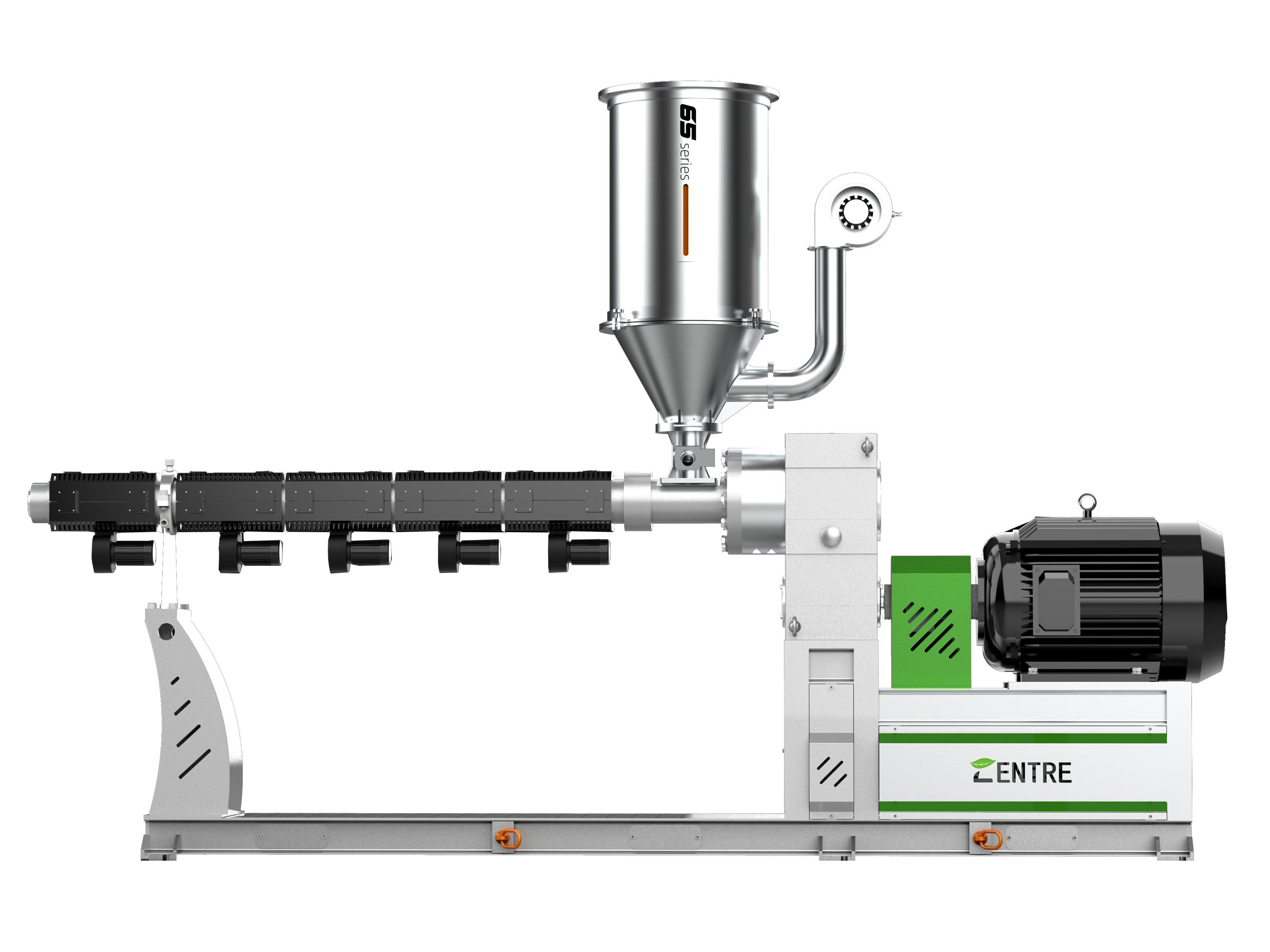

Vacuum tanks for pipe diameters up to 63 mm

- Special versions for exact vacuum control and water quantity control

- Fine vacuum control optional

- Dual or multiple chamber versions

- Switchable between full and spray bath

- Integrated blow-off and drying units

- Integrated dry-running protection for the vacuum and water pumps

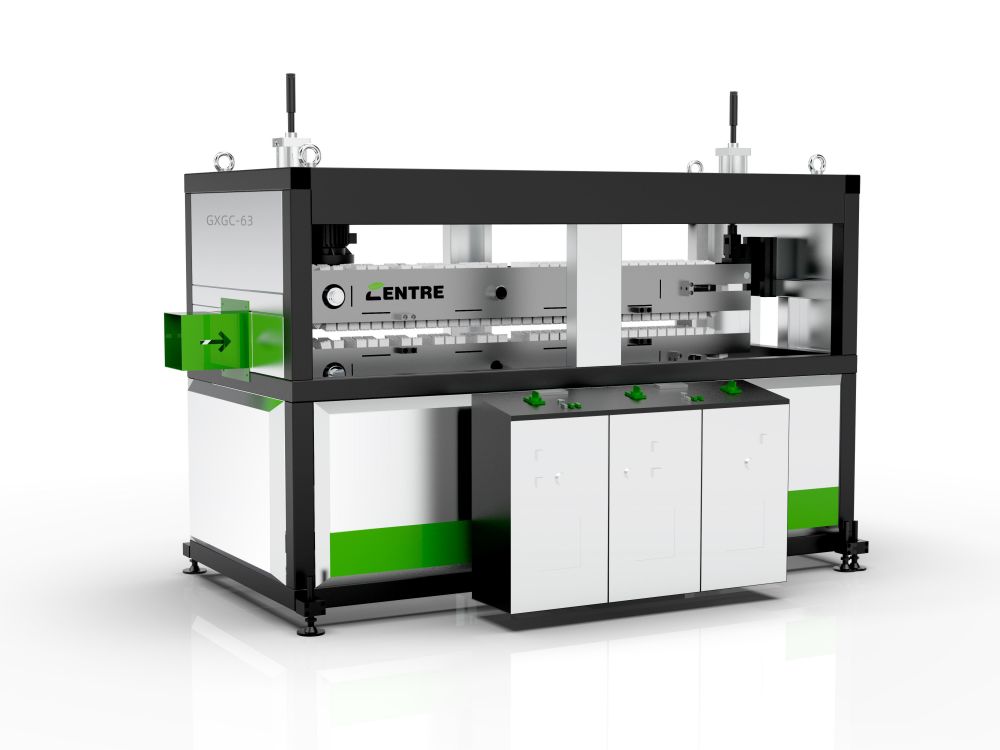

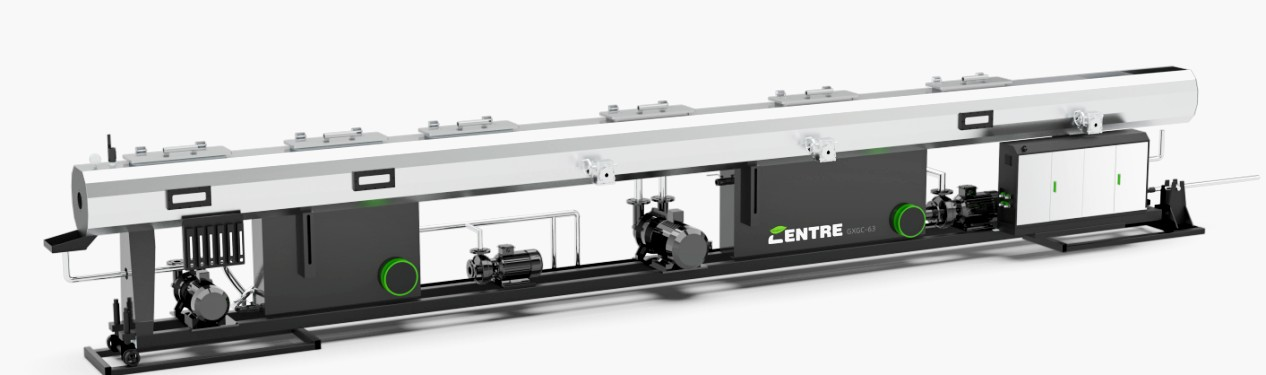

Vacuum tanks for pipe diameters up to 630 mm

- Tanks available in 6 m (single chamber), 9 m (dual chamber) with 1.5 m segments due to modular system

- Highly flexible configuration and long cooling section, due to barrier-free tank connection

- Extremely stable vacuum due to optimized process contro

- Highly advanced rail system aids the placement of components either under the tank or laterally

- All FDC components can be retrofitted at any time to single-chamber tanks

- Fast and easy sealing for vacuum generation through new lid design and longer service life of the sealings

- Symmetrical tank, which allows change of the operator side without structural alterations

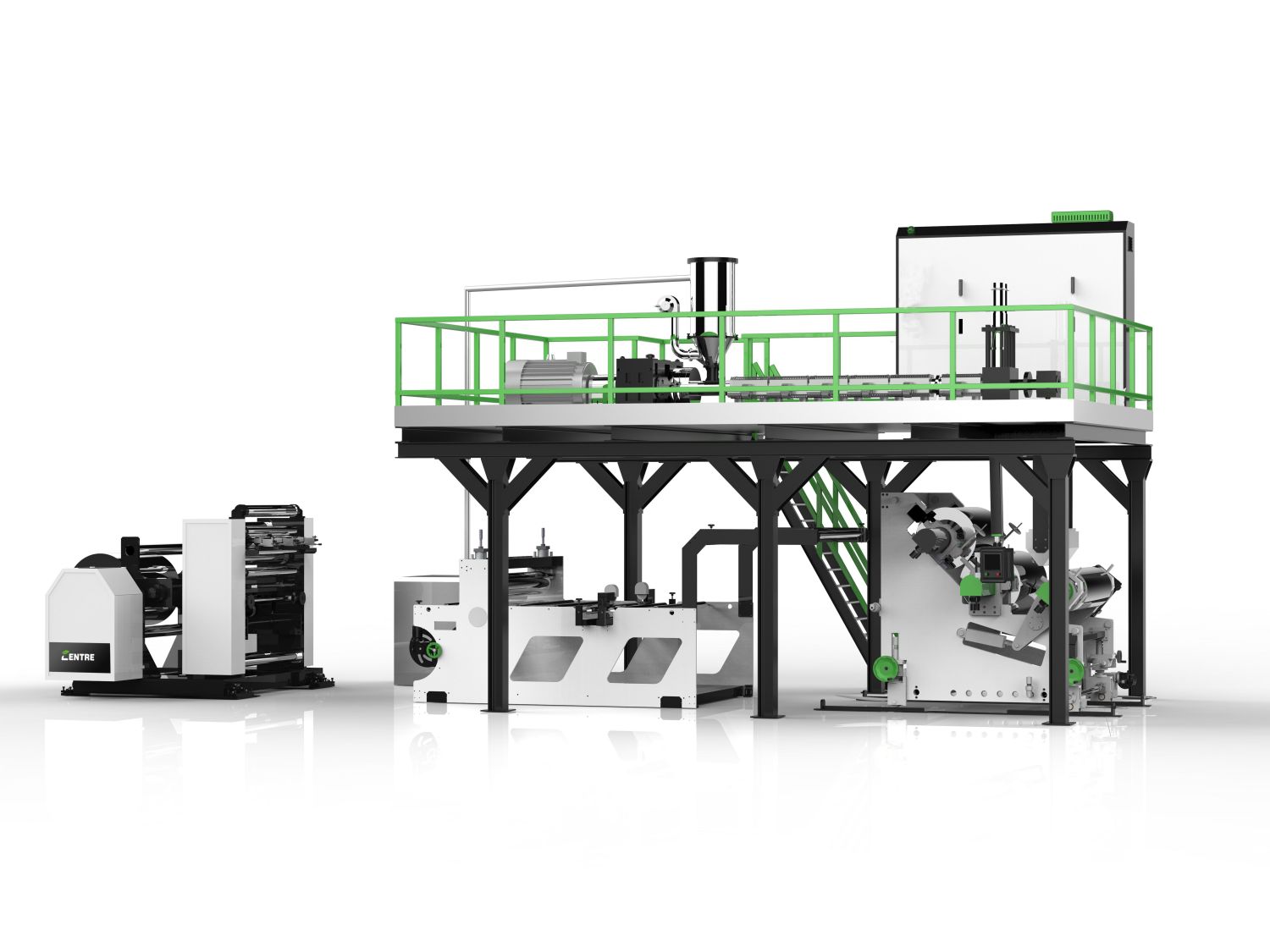

Vacuum tanks for pipe diameters from 800 mm and above

- Redundant water and vacuum pumps for safe operation and easier start-up

- Spray nozzle rods individually adjustable from the outside

- Double filter unit with automatic backwashing

- Changeover aids such as pulley and platforms inside the tank

- Easy access from above with the help of operator safety platform

Large diameter pipe extrusion of currently 1.600 mm (PVC) and 2.600 mm (HDPE)