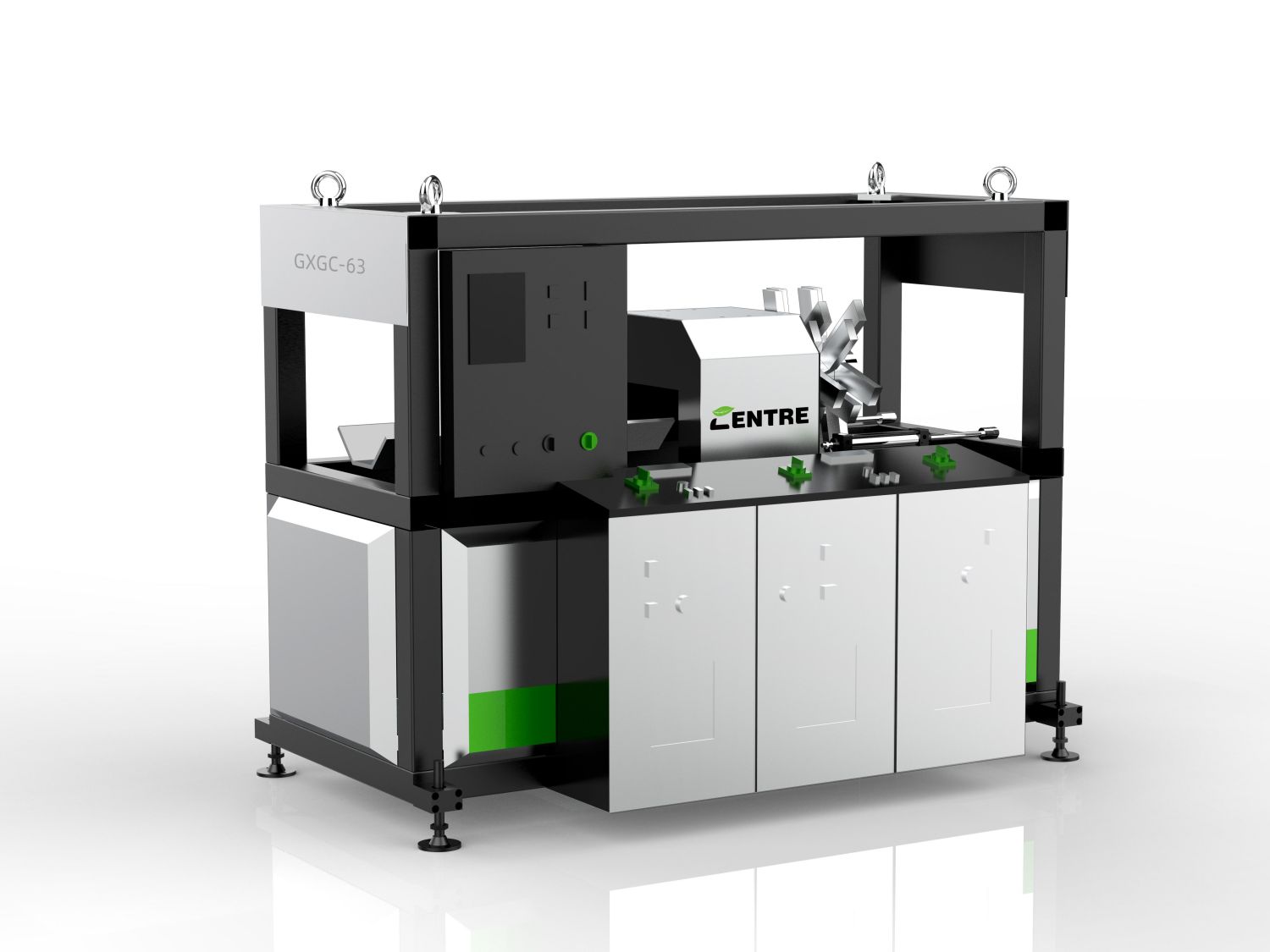

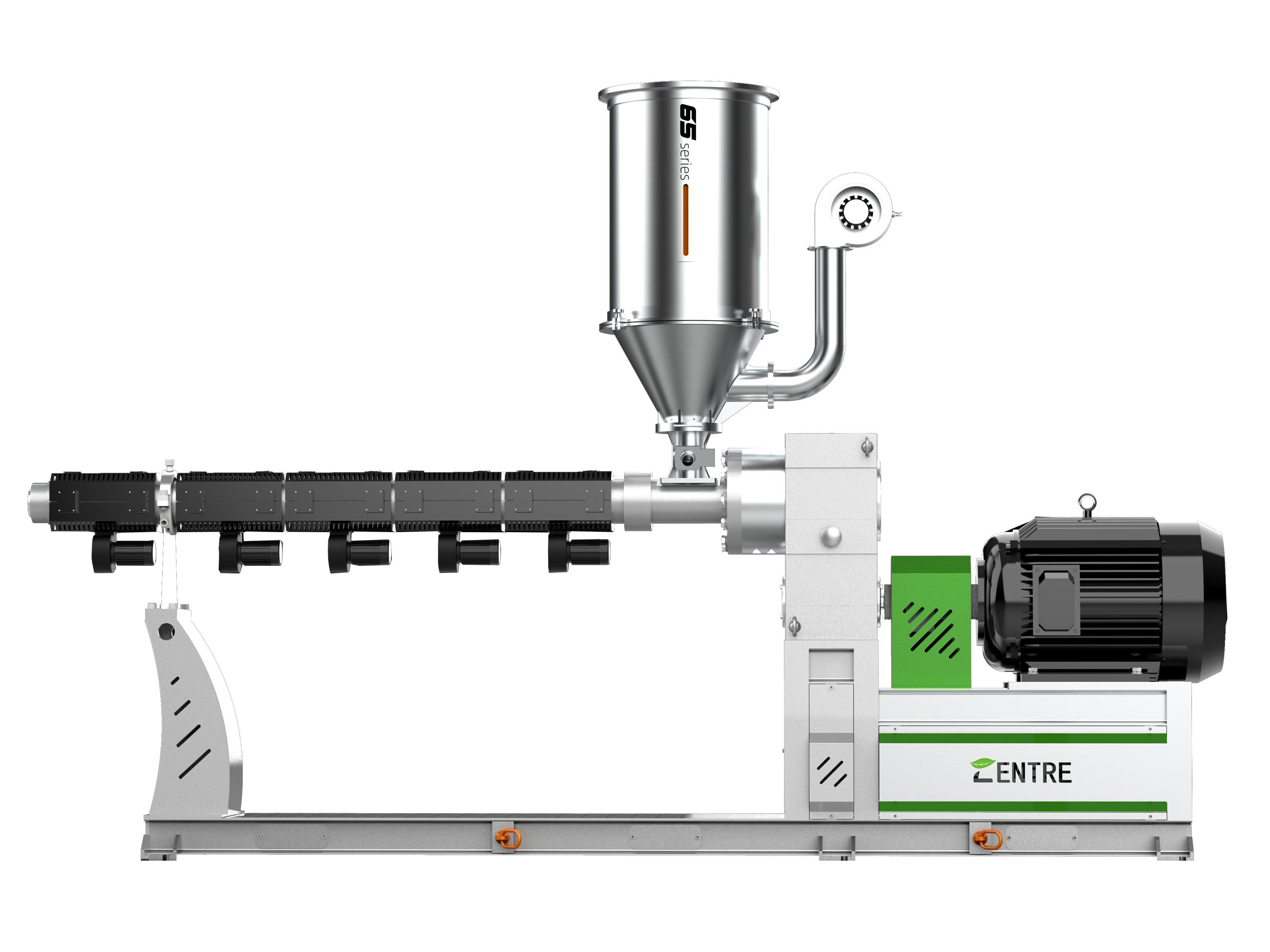

Haul-off Machine for Pipe Extrusion Line

Our Advantages

- Robust design

- Belts and caterpillars driven individually by 3-phase motors, optionally as servo drives

- High haul-off forces due to high motor torque and pressure cylinders

- High synchronization accuracy with coordinated drive motors

- Back pressure control for thin-walled pipes

- Electric adjustment of all caterpillars to pipe diameter

- Upper caterpillars with pendulum support and pneumatic contact pressure

- Integrated control via touch screen

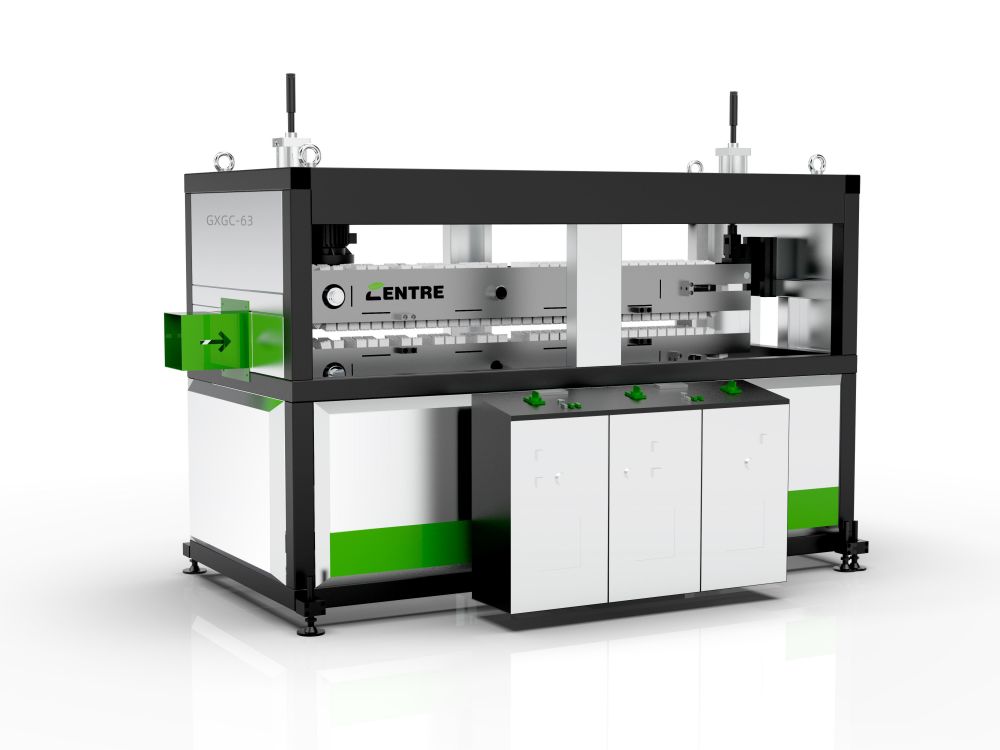

Our Offer

For pipes from 16 to 800 mm

- Starting from the double track extension, the design is tightened in the opposite direction, which can firmly lock the pipe and achieve different sizes from 16-800mm.

- Bottom caterpillars manually/electrically adjustable

- Start-up aid mounted on haul-off for saving space and synchronizing via pilot frequency

For pipes from 800 mm upwards

- Multiple caterpillar haul-offs (6-14) with V-shaped rubber studs

- Electrically adjustable caterpillars at top and bottom

- Start-up aids up to 180 kN tractive force, synchronized with haul-off via pilot frequency

- Deflection rollers and rope guides of start-up aids on tilting frame at the outlet end

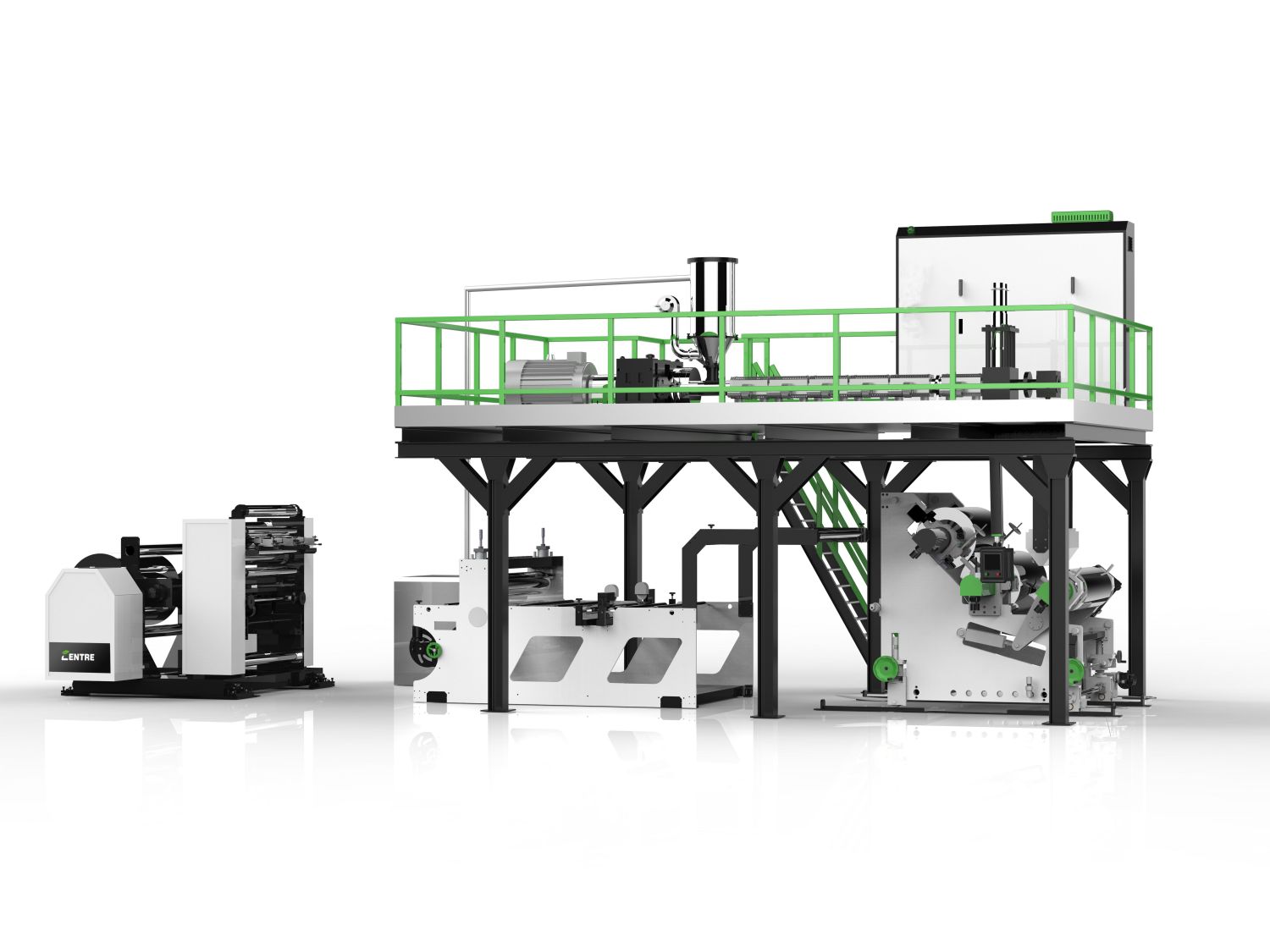

For small diameters up to 125 mm, especially composite, micro duct and drip irrigation

- Belt haul-offs with Poly-V belts for smooth running

- Extrusion speeds up to 300 m/min

- Extrusion height adjustable via hand wheel and fixed stop electrically adjustable

- Easy access for belt change due to quick belt change system

- Lateral pipe guides for high-speed extrusion

- Pivotable top support to compensate for twisting of the pipe during extrusion