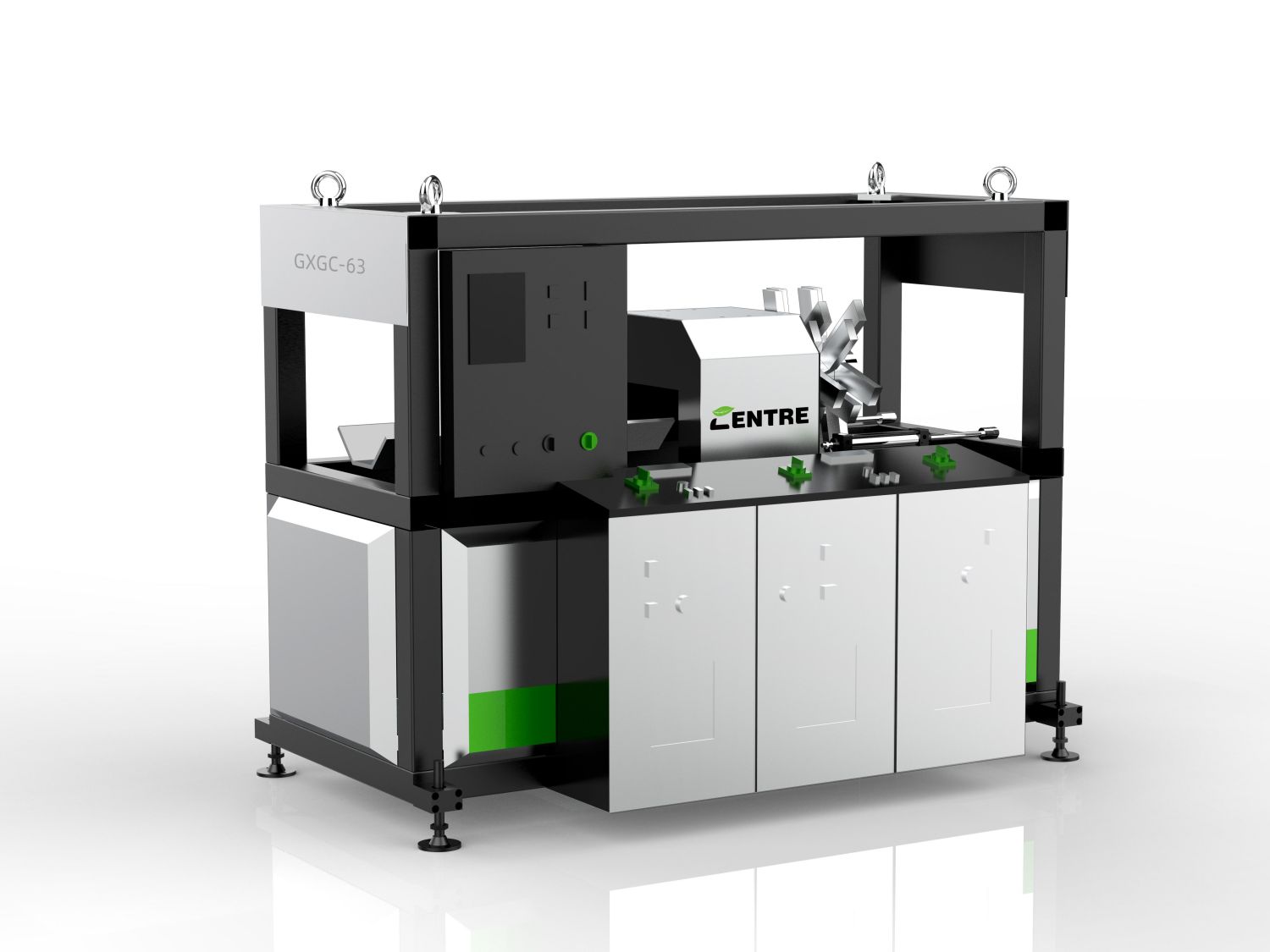

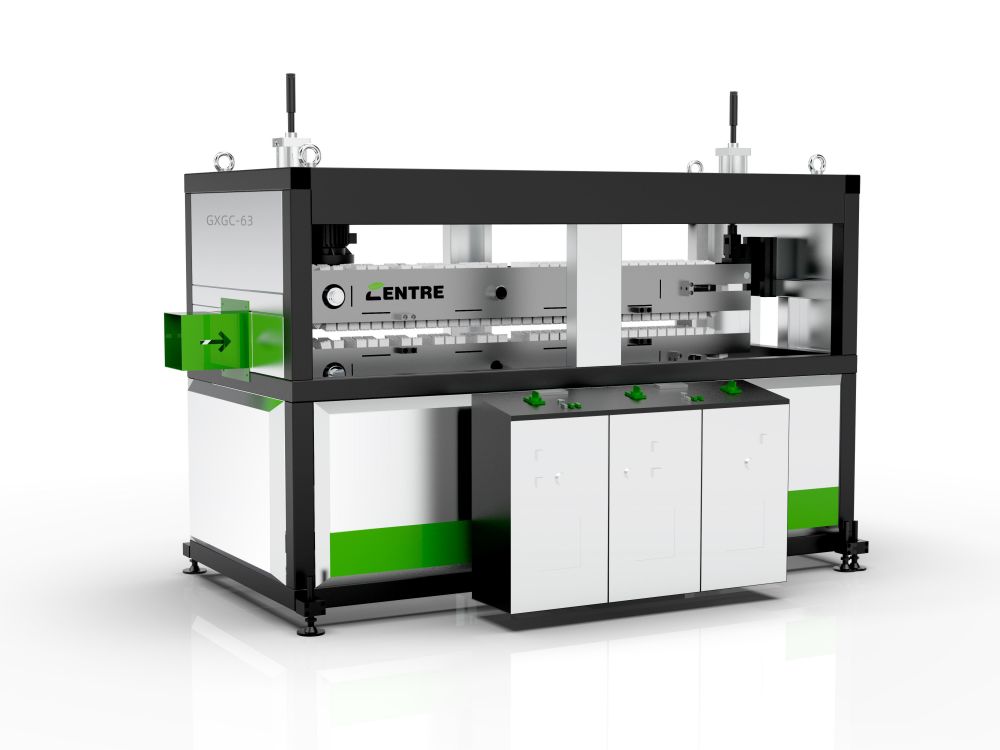

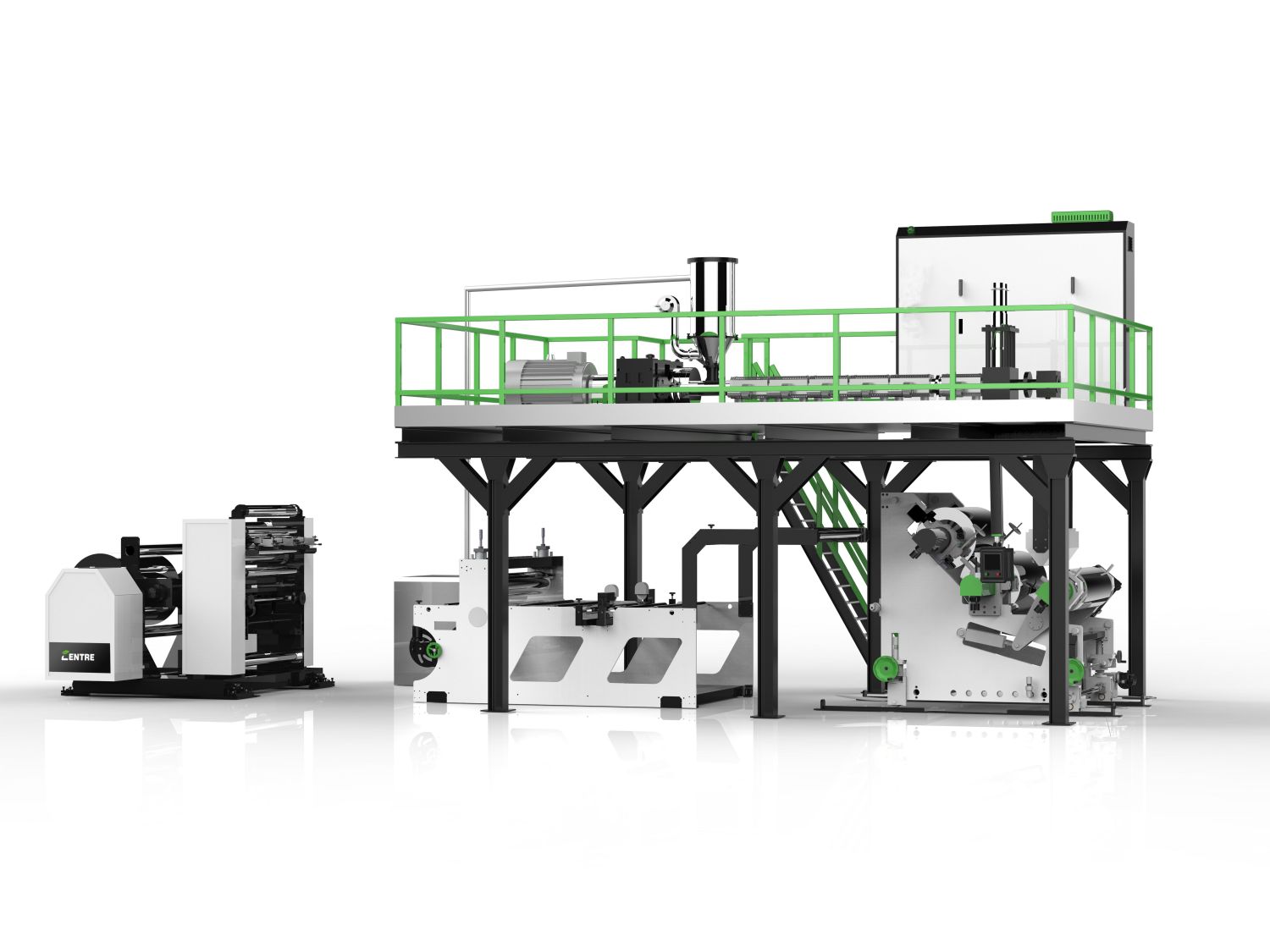

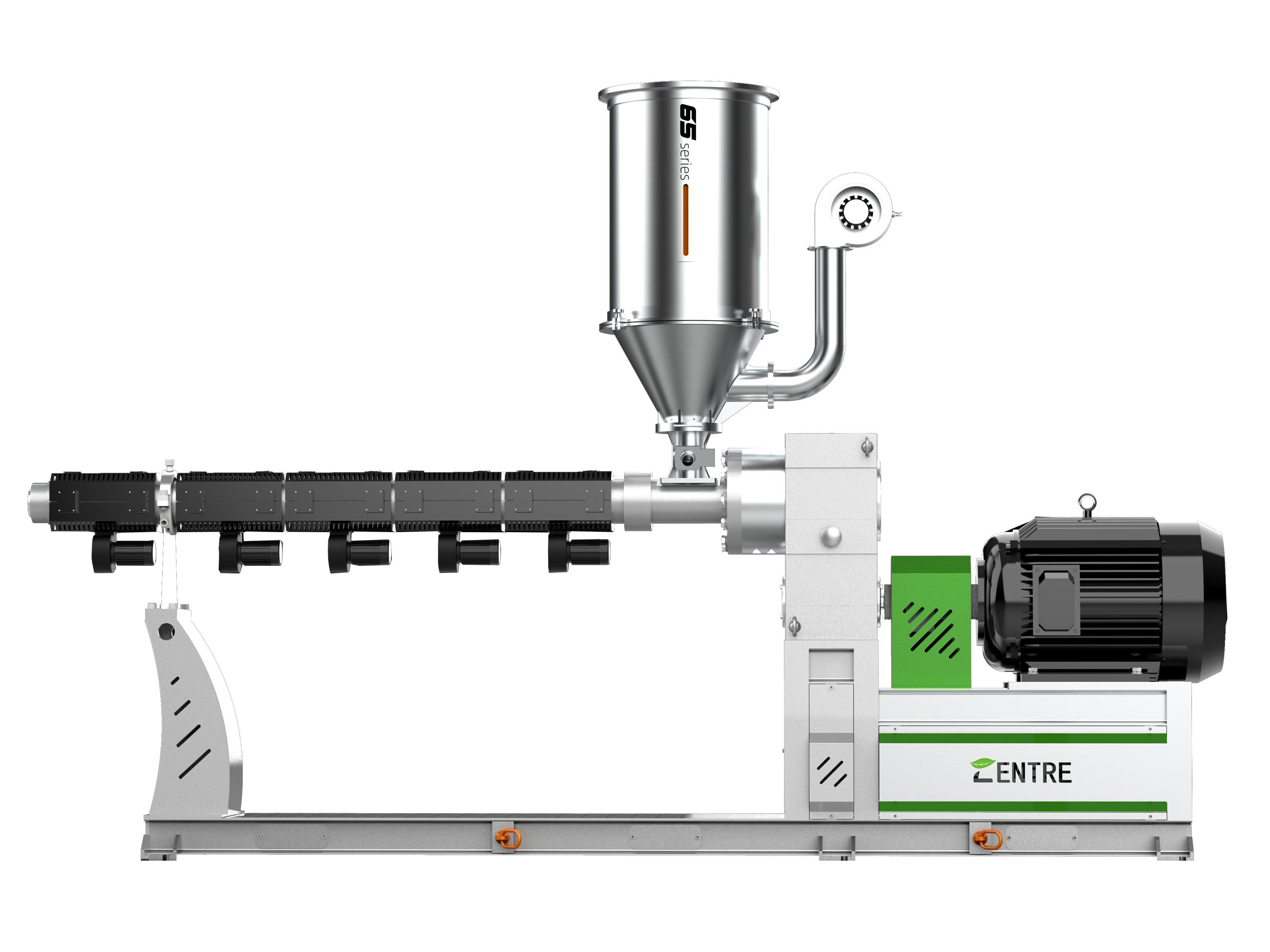

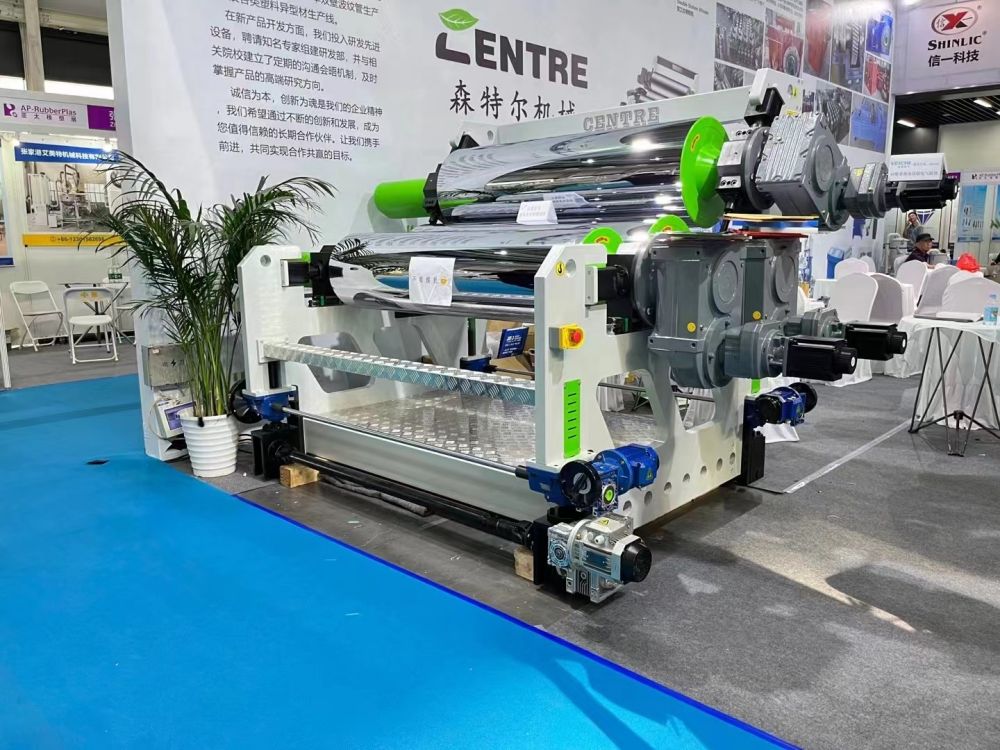

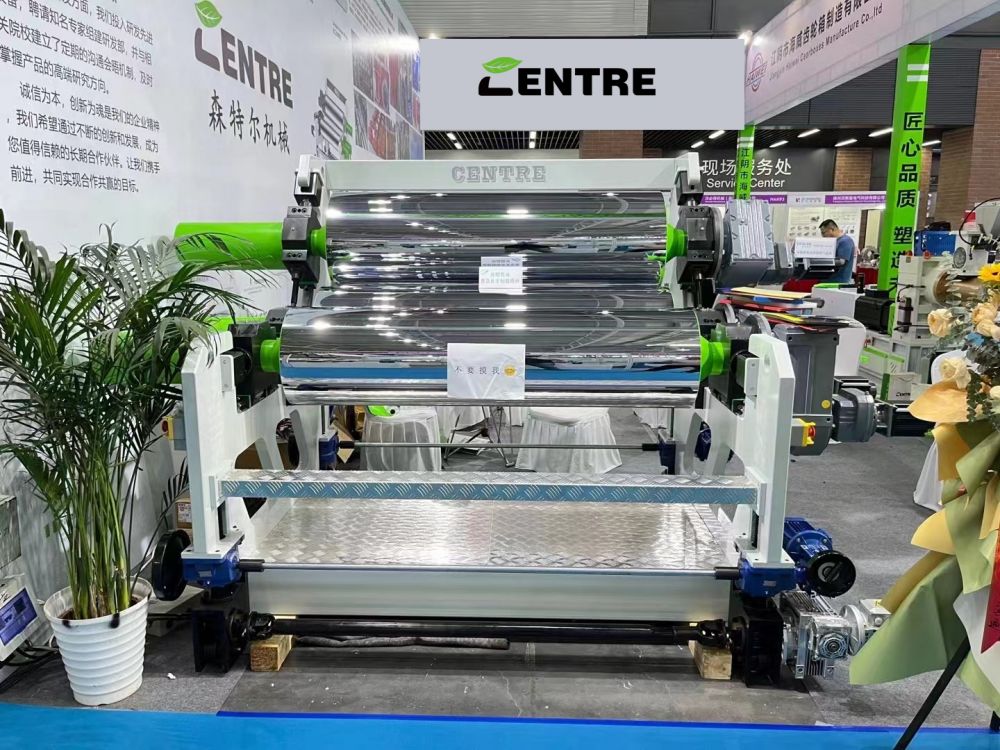

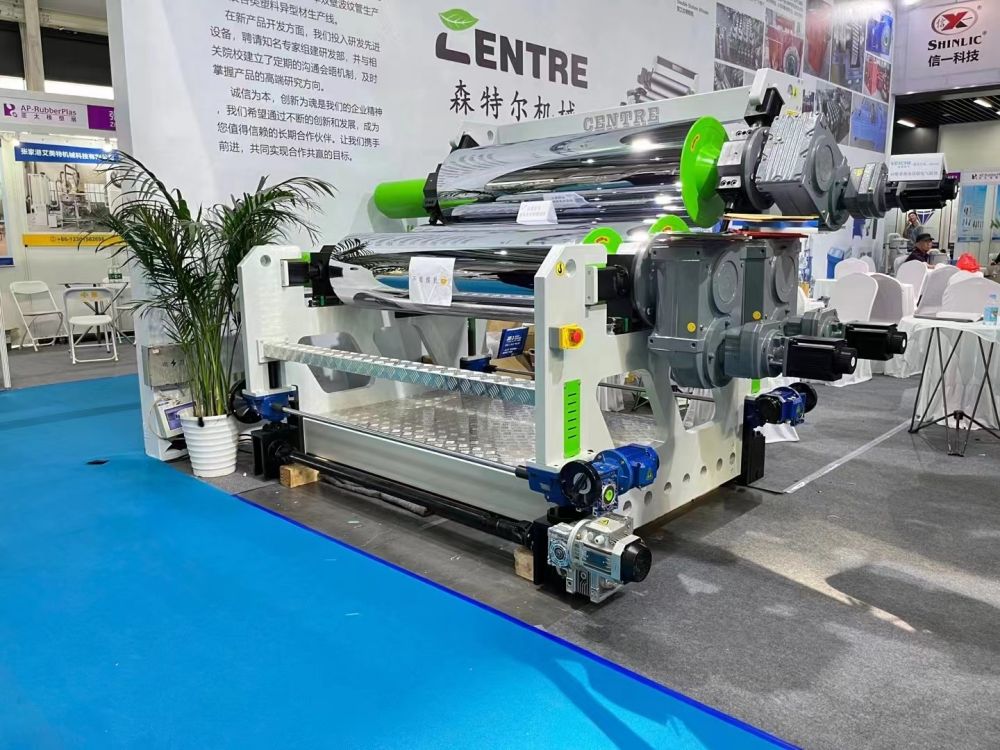

L Type Three-Roller Calender for Sheet Extrusion

This product is a new type of calendering machine, mainly used for calendering plastic sheets. It belongs to the technical field of plastic machinery and equipment.

Before the emergence of this new product, the traditional calenders were a vertical three-roller calender and a horizontal three-roller calender. The vertical type could only produce thick plastic sheets, and thin plastic sheets could not be produced. Adaptable, the horizontal type can only produce thin plastic sheets, and is not suitable for thick plastic sheets. The sheets produced by the above two forms of three-roll calenders have limitations in production and cannot be adapted to meet market requirements, and To produce thin sheets, the cost of investing in two types of equipment is required to meet production needs.

The purpose of this new design is to overcome the above shortcomings and provide a layout that uses a combination of vertical three-rollers and horizontal three-rollers. The upper and middle calender rollers adopt a vertical structure, and the middle and lower calender rollers adopt an oblique structure (including calendering). roller, reducer, bearing seat, linear guide rail, oil cylinder and thickness adjustment, etc.) and front and rear side plates (including base, work, support tube, front running wheel, rear running wheel, etc.) to optimize the vertical three-roller and inclined three-roller Two structures are developed and implemented. The clamping method between the upper calender roller and the middle calender roller and between the lower calender roller and the middle calender roller does not require the lifting and lowering of the screw of the worm gear elevator. The method has little effect on the thickness of the product for extruding thick plates, but it will be affected for extruding sheets. The thickness of the sheets will be uneven because there is a certain gap between the screw of the worm gear lifter and the worm gear nut. In order to solve the problem of clamping accuracy of the calender roller, the hydraulic cylinder clamping method is adopted, which can effectively eliminate the gap problem between the screw of the worm gear elevator and the worm gear nut. This not only solves the problem and improves the plate thickness accuracy, but also can One machine can be used for multiple purposes, greatly reducing equipment purchase costs.

The beneficial effects of this new product are plastic sheets of different thicknesses can be produced through this L-type three-roller calender to produce thin and thick sheets, which can meet the market requirements of plastic products of different thicknesses, while reducing equipment investment costs and increasing economic benefits and social benefits. Benefits, improving the market competitiveness of this kind of plastic three-roller calender.